Sign up for our popular daily email to catch all the latest EV news!

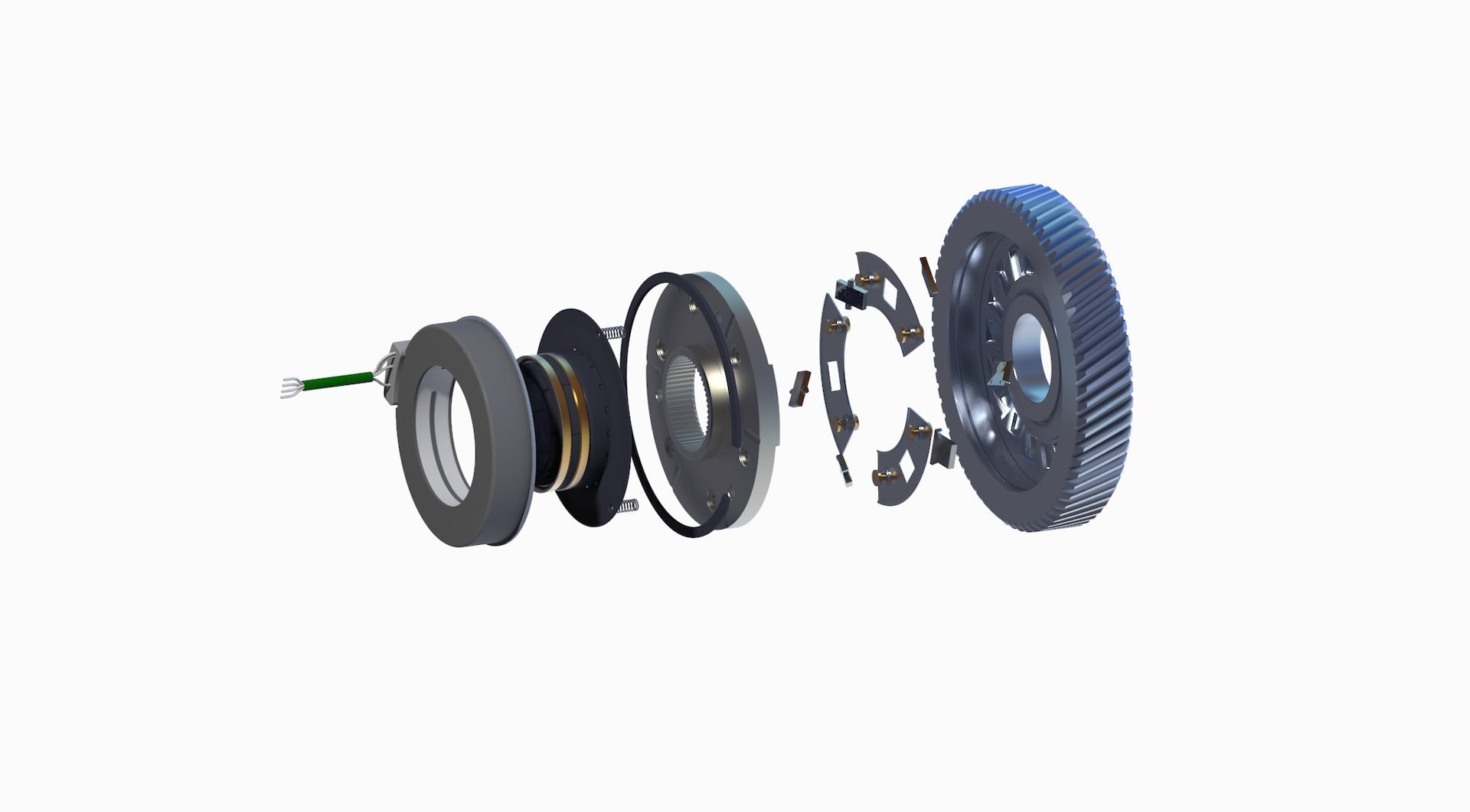

Amsted Automotive has unveiled its new Multi-Speed Shift Technology, set to debut in an electric vehicle (EV) in 2026. Designed to meet evolving consumer demands for improved efficiency, all-electric range, and performance, this technology enhances EV and hybrid electric vehicle (HEV) powertrains. By utilizing integrated One-Way-Clutch (OWC) functionality, the system optimizes cost, performance, and efficiency in EV and HEV drivetrains, offering smooth and quick shift transitions with simplified controls.

Key Highlights:

- New Multi-Speed Shift Technology launching in EV production in 2026.

- Utilizes integrated One-Way-Clutch (OWC) for optimized efficiency and performance.

- Offers smooth, quick shift transitions with simplified system controls.

- Incorporates proven Dynamic Controllable Clutch (DCC) technology used in current EV models.

Amsted Automotive’s Multi-Speed Shift Technology aims to improve the efficiency, range, and performance of next-generation EV and HEV propulsion systems. This technology integrates One-Way-Clutch (OWC) functionality, which enhances system function and minimizes costs. It also provides flexible solutions that achieve smooth and efficient shifts while simplifying the control system compared to conventional technologies. A white paper on this innovation is available for download at Amsted Automotive’s website.

The new multi-speed technology incorporates Amsted Automotive Dynamic Controllable Clutch (DCC), already in use in a production EV all-wheel-drive vehicle. The technology supports both parallel-axis and co-axial powertrain systems, with one variation eliminating friction clutches to reduce drag and improve efficiency and sustainability.

The Amsted One-Way Clutch offers multiple benefits over traditional dog-clutch systems, including:

- No blocked or interrupted shifts

- No ratcheting during shifts

- Simplified system controls

- Additional functionality such as park-lock

- Easier calibration, reducing engineering loads

In 2021, Amsted Automotive brought together Means Industries Inc., Transform Automotive, SMW Manufacturing, and Burgess-Norton Mfg. Co., Inc. to form a comprehensive technology team. With a robust global manufacturing footprint of 21 facilities across North America, Europe, and Asia, Amsted Automotive produces over 100 million components and assemblies annually. Their expertise is strategically aligned to lead in precision products and efficiency solutions for electrified, hybrid, and internal combustion engine (ICE) propulsion systems.

Sign up for our popular daily email to catch all the latest EV news!