Sign up for our popular daily email to catch all the latest EV news!

The BMW Group has unveiled its groundbreaking 800V electric drive technology for the Neue Klasse lineup, marking a significant leap in EV performance and efficiency. Showcased at the Tech Days event in Landshut, this next-generation system features sixth-generation BMW eDrive technology with innovations in high-voltage batteries, energy management, and electric motors. The first Neue Klasse model is set for series production later this year at Plant Debrecen in Hungary, promising enhanced charging speeds, extended range, and modular flexibility for diverse vehicle types. The integration of BMW 800V technology truly sets the stage for future innovations.

Key Highlights:

- 800V technology enabling 30% faster charging and 30% longer range.

- New cylindrical cell batteries with 20% higher energy density.

- BMW Energy Master control unit optimizes power supply and battery performance, ensuring the efficiency of the BMW 800V system.

- Flexible SSM and ASM motor types for tailored driving experiences.

- Bidirectional charging as standard on Gen6 batteries.

- Global “local for local” production strategy for high-voltage batteries.

- Enhanced recycling processes and sustainable battery material sourcing.

- Thermal management improvements for optimal range and charging performance.

Dr. Joachim Post, BMW AG Board Member, emphasized the company’s technology-open approach, stating, “We want to offer our customers the best drive concept for every need while leading in electric mobility.” This is particularly true with the introduction of the BMW 800V system.

Gen6 eDrive: Speed, Range, and Flexibility

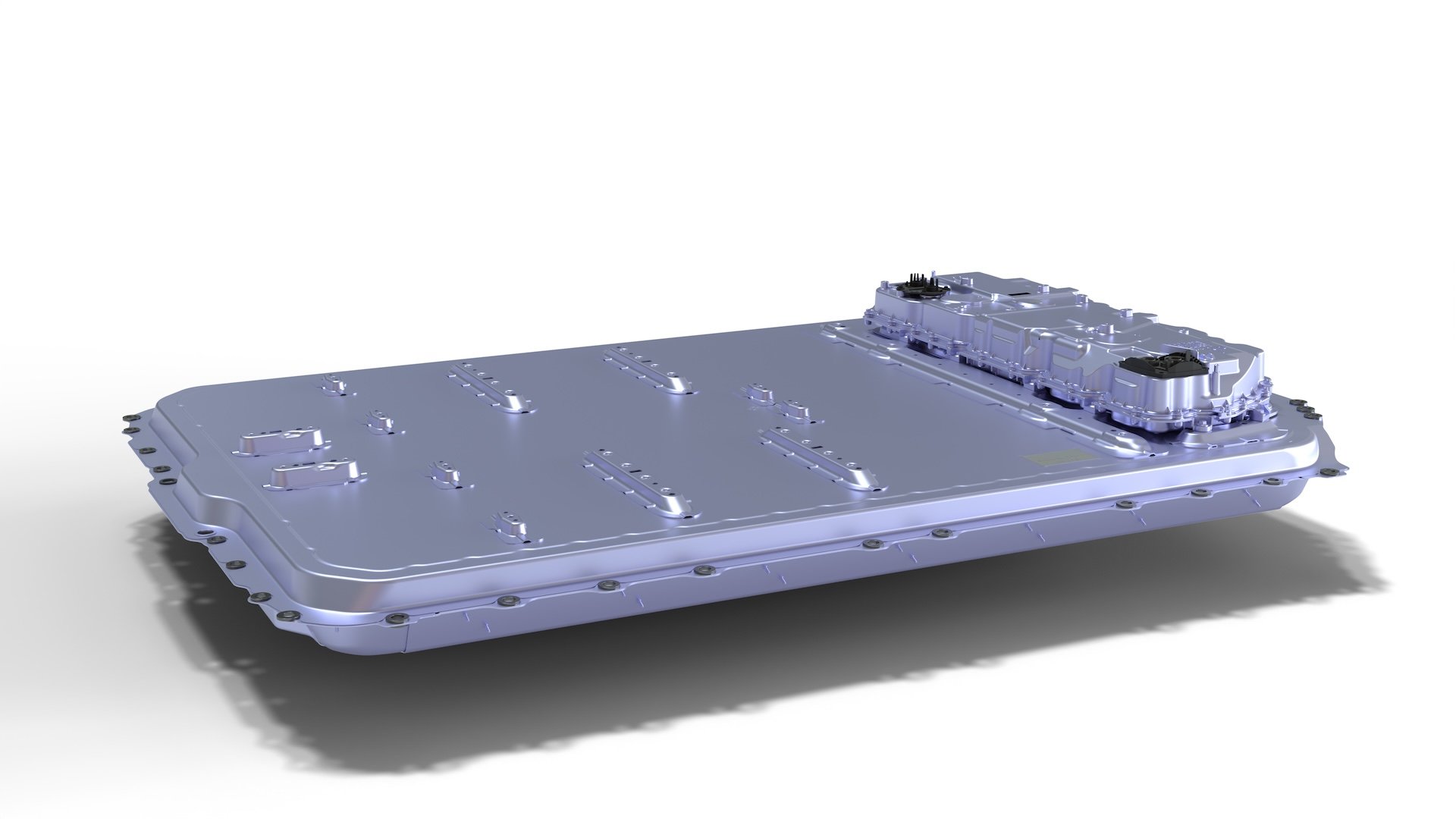

The Gen6 high-voltage battery delivers a 30% boost in both charging speed and range, supported by 800V architecture. The slimmer design integrates directly into vehicle structures, maximizing space and efficiency. The Energy Master control unit further optimizes energy flow, enabling remote software updates and ensuring real-time performance enhancements for the BMW 800V enabled vehicles.

Modular Electric Motors for Every Driver

The Gen6 system introduces modular electric motors—electrically excited synchronous motors (EESM) and asynchronous motors (ASM)—offering flexible powertrains across the Neue Klasse range. This approach reduces energy losses by 40%, lowers costs by 20%, and cuts weight by 10% compared to previous models, highlighting the advantages of using BMW 800V technology.

Sustainable Production and Recycling

BMW’s “local for local” strategy ensures battery production near key vehicle plants in Europe, China, Mexico, and the USA. Partnerships with companies like SK tes enable cobalt, nickel, and lithium recycling, reinforcing BMW’s commitment to a circular economy. The company is also pioneering direct recycling methods, reclaiming valuable materials from battery production waste. These efforts ensure sustainable practices as the BMW 800V system is incorporated into more models.

Looking Ahead: Innovation and Scalability

Production of Gen6 components will begin at Plant Steyr (Austria) in 2025, with an annual capacity of 600,000 electric drive units. Simultaneously, Plant Landshut will produce the Energy Master and develop advanced light metal housings using patented Injector Casting technology, further strengthening BMW’s EV portfolio with the integration of BMW 800V technology.

The Neue Klasse’s sixth-generation eDrive represents a major leap forward, combining cutting-edge battery technology, efficient electric motors, and a sustainable manufacturing approach to redefine electric mobility for years to come with the BMW 800V system leading the charge.

Sign up for our popular daily email to catch all the latest EV news!