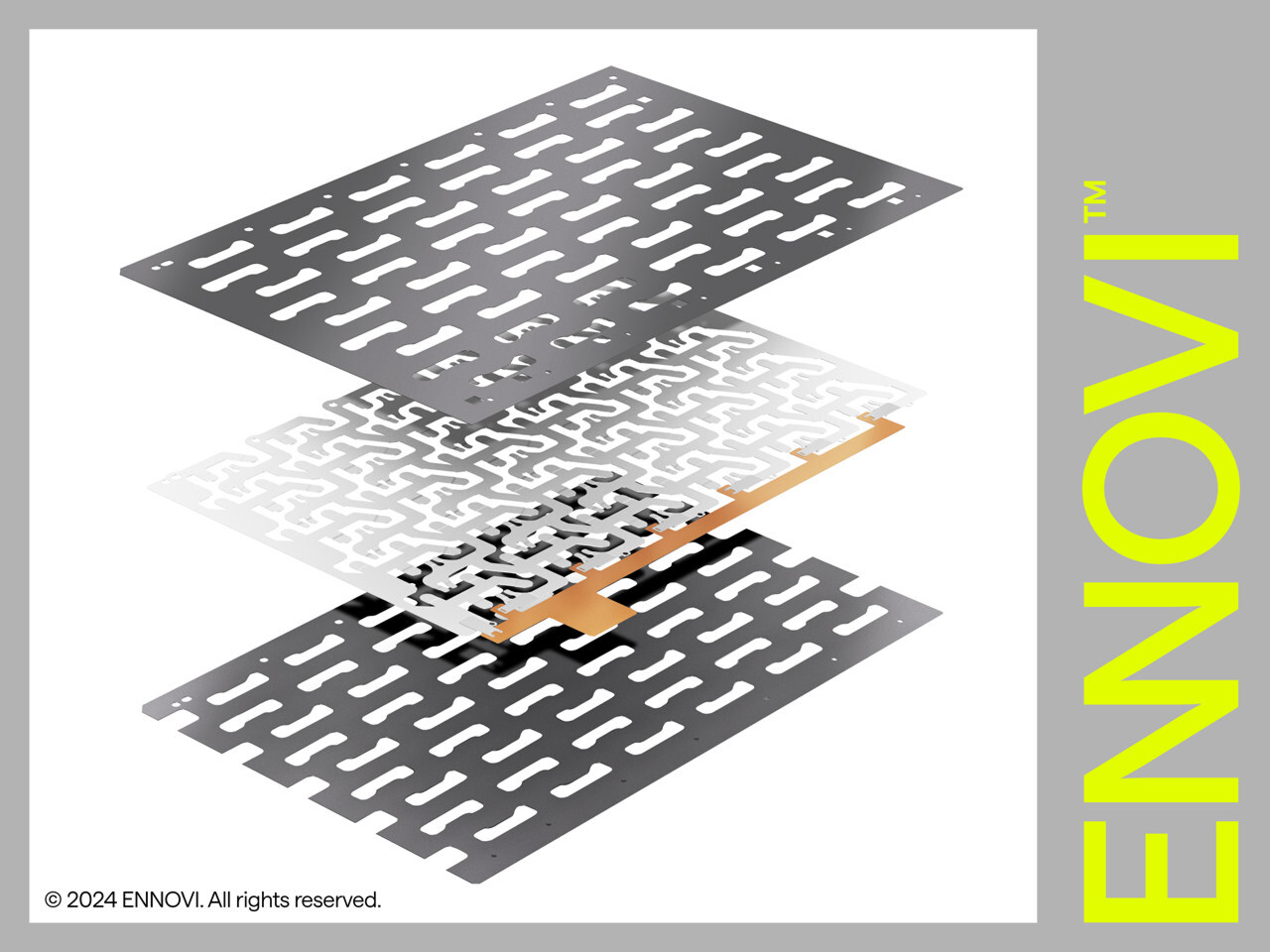

ENNOVI, a leading mobility electrification solutions provider, has developed a new cell contacting system (CCS) lamination method for electric vehicle (EV) batteries, which optimizes both manufacturing efficiency and environmental sustainability. By utilizing advanced polyethylene terephthalate (PET) insulation foils and adhesives, ENNOVI aims to enhance the reliability and lifespan of EV batteries, offering a more adaptable and streamlined approach compared to traditional assembly methods.

Key Highlights:

- Innovative Lamination Method: ENNOVI introduces a novel lamination technique that replaces older, bulkier methods, significantly reducing the weight and complexity of battery modules.

- Pre-Tested Materials: The company has tested various PET foils and adhesives to create a recommendations database, helping to expedite the design process and improve material efficiency.

- Enhanced Flexibility and Efficiency: The new lamination process offers both hot and cold applications, providing greater flexibility to meet diverse manufacturing needs.

- Environmental and Energy Savings: The optimized process aims to reduce the environmental footprint of manufacturing EV batteries, focusing on reducing or eliminating the use of traditional adhesives.

Till Wagner, Product Manager for Energy Systems at ENNOVI, stated, “Our move towards lamination signifies a major leap in our ability to position collectors with precision, without the mechanical constraints imposed by conventional methods. By curating a database of pre-tested PET foils and adhesives, we not only accelerate CCS design but also simplify the assembly process, opening up new possibilities for material and energy savings.”

The shift towards a more sustainable, efficient manufacturing process aligns with the industry’s goal of enhancing structural integrity and reducing lifecycle impacts. ENNOVI’s advancements in lamination technology are set to improve the efficiency and sustainability of the manufacturing cycle, positioning the company as a leader in the next generation of EV battery module design and assembly.

“Our goal is to move beyond traditional adhesives, leveraging cutting-edge techniques to achieve a stronger, more sustainable bond,” adds Wagner.

About ENNOVI:

Headquartered in Singapore, ENNOVI is a world leader in designing and manufacturing customized interconnect and high-precision system solutions for the EV market. With over 8,000 employees in 15 locations globally, the company is committed to responsible and environmentally friendly practices. Learn more at www.ennovi.com.

This detailed approach showcases ENNOVI’s commitment to pioneering within the EV sector, driving forward with innovations that enhance product reliability and manufacturing processes, while also prioritizing environmental considerations.

Sign up for our popular daily email to catch all the latest EV news!