Hanford Facility Has a Production Capacity of Approximately 10,000 Vehicles Per Year and will be Ready to Begin Production Within 12 Months of the Closing of its Merger with PSAC

LOS ANGELES – Faraday Future (“FF”), a California-based global shared intelligent mobility ecosystem company, today announced its global manufacturing strategy with new video footage, demonstrating its capabilities for its class-defining ultimate-intelligent tech-luxury electric FF 91. The FF 91 is FF’s flagship product offering, and features an industry-leading 1,050 HP, 0-60 mph sprint in less than 2.4 seconds, zero gravity rear seats with the industry’s largest reclining seat angle of 60 degrees, and a revolutionary user experience designed to create a mobile, connected, and luxurious third Internet living space.

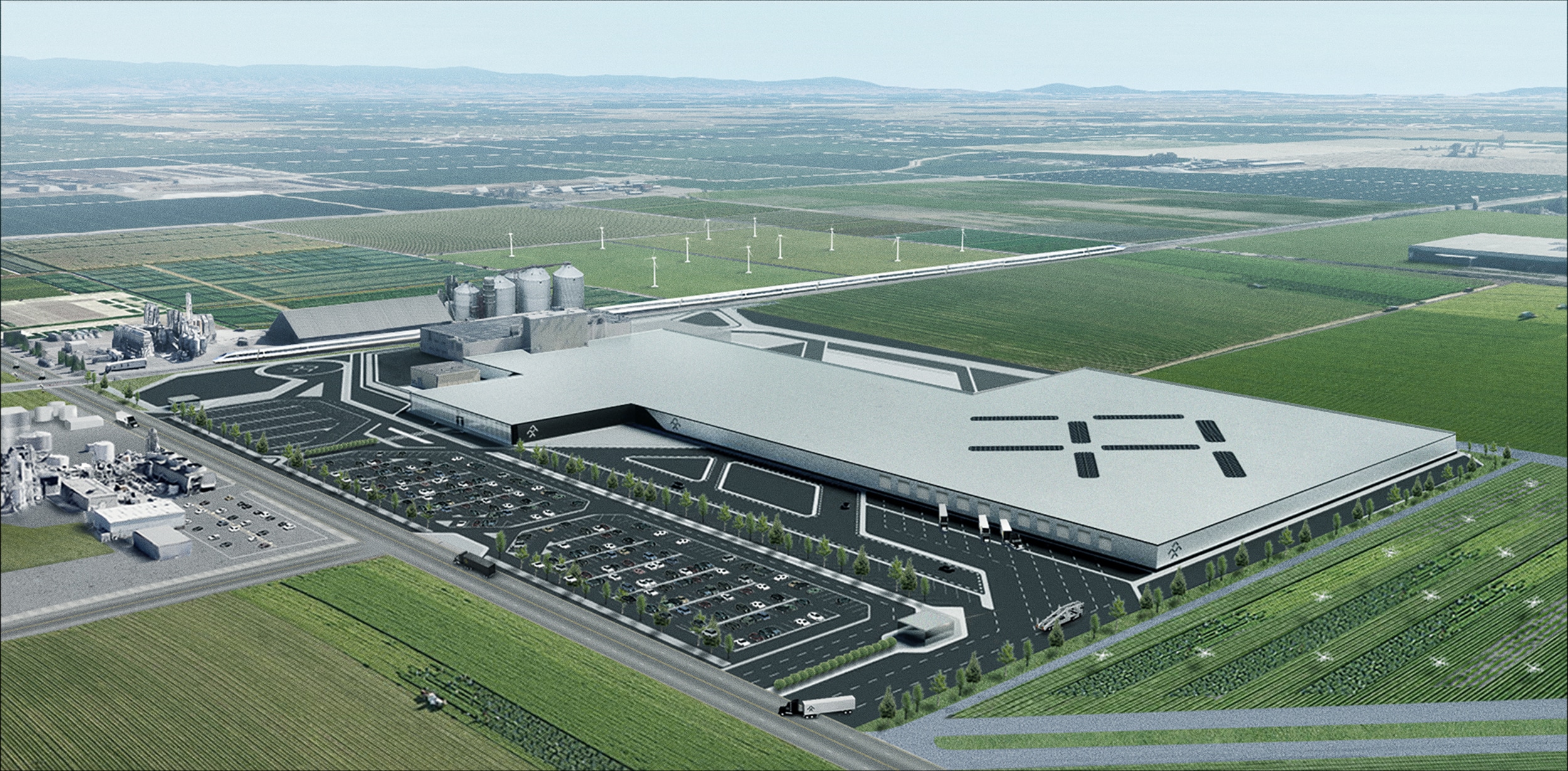

To implement a capital light business model, FF has adopted a global hybrid manufacturing strategy. The company’s primary manufacturing of the FF 91 will take place at its 1.1 million square-foot refurbished facility in Hanford, California. The existing facility has the infrastructure in place needed for production, significantly reducing both costs and lead time. The facility has a production capacity of approximately 10,000 vehicles per year and is expected to be ready to begin production within 12 months of the closing of its merger with PSAC. FF has retained the services of Ware Malcomb, a leading full service international design firm, to finalize FF’s architectural planning, interior design, and civil engineering for its Hanford manufacturing facility.

You Might Also Like: Faraday Future to Go Public via Merger, $1 Billion in Proceeds

“FF has already completed significant investment at our Hanford manufacturing facility, and with the additional funding from our merger with PSAC, we anticipate that the plant will be up and running in the near future,” said Dr. Carsten Breitfeld, Global CEO of FF. “Since its inception, FF has always been committed to offering state of the art technologies including software, internet, and artificial intelligence. This is what sets us apart from the competition, and what we will be focusing our efforts on once production is underway.”

FF is collaborating with a leading contract manufacturing partner in South Korea for future models. The company has signed an agreement with Myoung Shin for additional capacity to manufacture vehicles. Production has been agreed to be launched in a former GM plant with key retained personnel in vehicle production and ramp-up. FF is also exploring the possibility of additional manufacturing capacity in China through a contract manufacturing opportunity.

FF is currently preparing to merge with Property Solutions Acquisition Corp. (“PSAC”) (NASDAQ: PSAC), a special purpose acquisition company (SPAC). The previously announced merger, expected to close in July 2021, will result in the combined company listing on the Nasdaq Stock Market under the new ticker symbol “FFIE” after the closing. The I in “FFIE” represents Intelligent and Internet, and E represents Ecosystem and Electric. FF’s flagship electric vehicle (“EV”) – FF 91 – is planned to be launched within 12 months of the closing of the merger.