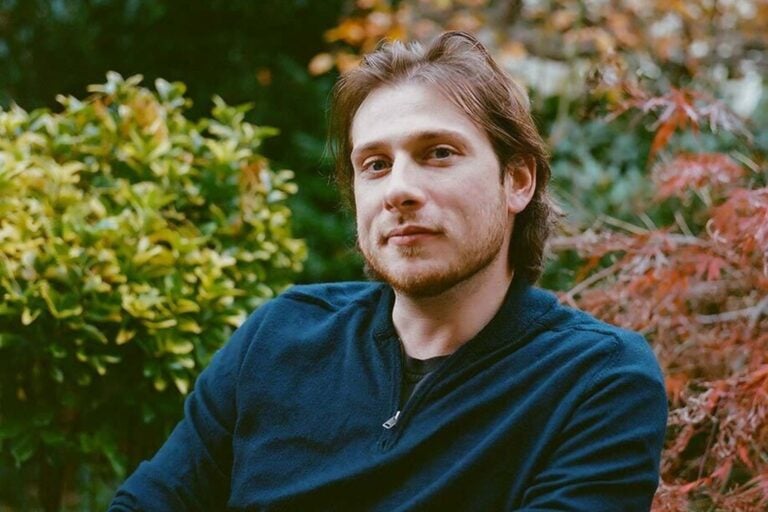

Ben DeLand is Director of Electrical Hardware Engineering at GKN Automotive. Based in Auburn Hills, he leads the development of Traction Inverters and Electronic Control Units for GKN’s eDrive and All-Wheel Drive systems. Ben joined the business in 2015, holding a variety of engineering roles focused on building GKN Automotive’s electronics capabilities.

The EV Report recently had the opportunity to connect with Ben and learn more about GKN Automotive and the role it plays in the EV market.

Who is GKN Automotive?

GKN Automotive is the global leader in drive systems, with over 80 million driveshafts delivered annually (ICE, hybrid, & EV) and over 2 million eDrive systems delivered to date that are propelling electric and hybrid vehicles. We are expert system development and system integration partners for our customers, offering an agile and customer-focused development process.

Give us a quick background on GKN Automotive. How did GKN build itself into its current position as a leading drive system supplier?

GKN Automotive has a rich and extensive heritage, with the company’s origin reaching back to iron production in the middle of the 18th century. In the 1950s, GKN utilized its substantial experience and scale with steel production to enter the automotive industry.

Driveshafts (Torque Transfer)

After entering auto, GKN Automotive quickly became driveshaft innovators and transformed the industry with its Constant Velocity Joint (CVJ) technology. In the driveshaft market, GKN has been absolutely dominant for more than half a century, enjoying >40% of the market share.

AWD Systems (Torque Management)

The extensive experience with Driveshafts (Torque Transfer) gave us the opportunity to step into Torque Management opportunities. Through natural growth and the acquisition of Getrag’s Driveline business, GKN Automotive became a leading AWD supplier. This set the foundation for us to be eDrive leaders.

How has being a leader in AWD systems helped GKN Automotive in the innovation of eDrive technology?

The development of AWD systems provided the foundation for eDrive system development (Torque Generation).

- With AWD, we built our experience in gearsets and actuators, which directly translates to eDrive gearbox development.

- AWD allowed us to develop complex electronics and software systems with state-of-the-art safety and cyber security features. This prepared us for the justifiably rigorous safety standards of eDrive systems

- AWD allowed us to be system integrators. It forced an understanding of vehicle integration and the complexities of harmonizing your system with the vehicle. As drivers demand as little vibration, noise, and harshness from their vehicle, this is a critical skill, which few suppliers have.

How much AWD technology carries over to eDrive technology?

A surprising amount! First, eDrive systems contain the Torque Management devices that were previously provided by separate AWD Systems. Differential systems and disconnect devices can be applied directly to eDrive systems with little modification. Additionally, bearings systems, breathing systems, and lubrication systems are extremely similar between AWD and eDrive. The electronics used on AWD provide the foundational aspects of the controller in an eDrive system.

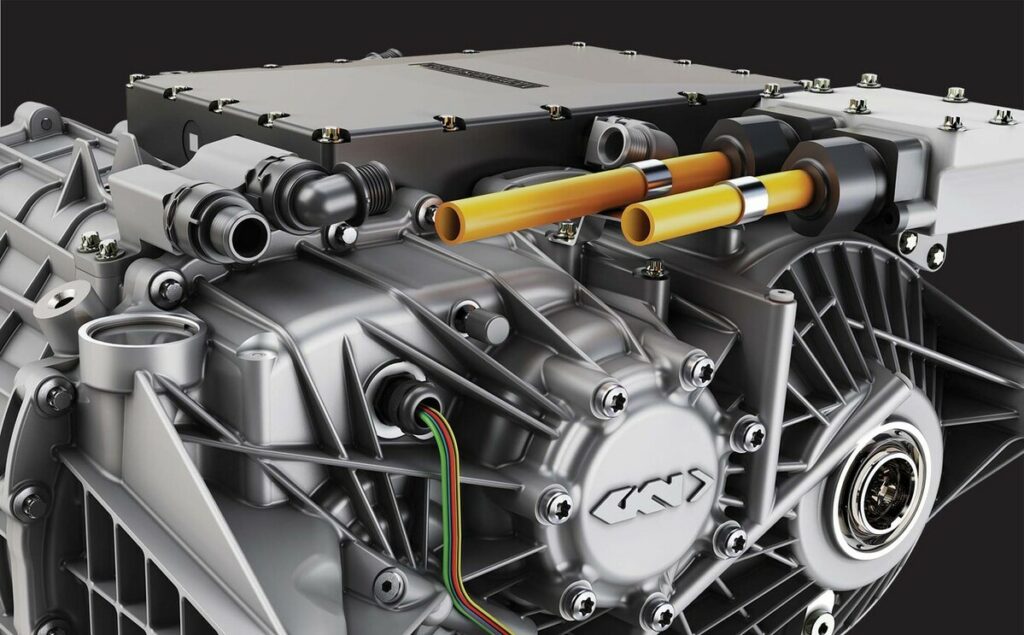

What systems are unique to eDrive systems and electrification?

Aside from some minor gear uniqueness, the obvious new system is the traction motor. While GKN Automotive’s AWD experience provided experience with low-voltage motors, the traction motor is a high-voltage, high-power device that is responsible for the torque generation that propels the vehicle. Our engineering team in Zumaia, Spain has been innovating, however, for many years with several traction motors in production. So while different than AWD, we have substantial experience with traction motors and have made cutting-edge designs with advanced cooling features.

How does GKN Automotive support the electric vehicle industry? or What role does GKN Automotive play in the EV market today?

GKN Automotive was an early adopter in eDrive systems for hybrid vehicles and early EVs, supplying electric drive systems for over 20 years. We offer a high level of product flexibility for our customers. The complexity ranges from providing full eDrive systems (motor + inverter + gearbox) with vehicle integration support down to providing individual components that our customers can integrate into their own systems. For example, GKN has a strong reputation for gearbox design & manufacturing. Many of our customers wish to have eDrive system ownership – they may design & manufacture the motor & inverter but ask GKN to design the gearbox.

GKN Automotive is also the leading sideshaft supplier for EVs, which have some key differences from combustion engine side shafts.

What has been the biggest challenge in transitioning your technology to electrification?

The pace of transition to electrification in the market has been exciting the past couple of years. We could consider a couple of trends:

The customer demand for speed, acceleration and high torques has thus far been insatiable.

This race for power places unique technical demands on the eDrive systems GKN Automotive supplies. The goal is to squeeze every possible ounce of power out of the unit, and this has pushed our technology toward advanced cooling mechanisms and sophisticated controls methods.

Range anxiety for consumers is a continued barrier for mass adoption of EVs

Our customers consistently demand higher and higher efficiency levels from the eDrive system to get the longest possible range out of their batteries. Reaching these efficiency standards has driven our engineers to innovate and challenge the status quo of our mature systems. Efficiency is a huge focus area for GKN Automotive and one which our engineers are excited to be developing. Achieving high levels of efficiency not only serves our customer needs, but also helps us achieve our mission of creating a more sustainable world.

To learn more about GKN Automotive, go HERE.