Dhanendra Nagwanshi is Global Marketing Leader for EV Batteries & Electricals Automotive Business, Petrochemicals with SABIC. Currently, he leads a global team that focuses on enabling the automotive industry across the full value chain to address some of its critical challenges in vehicle electrification. His team is making significant progress in identifying and developing solutions that can support the optimization of battery packs and electrical systems with thermoplastic materials.

Dhanendra has more than 35 U.S. patents to his credit, has published about a dozen papers, and presented at prominent automotive industry conferences, including the International Technical Conference on the Enhanced Safety of Vehicles (ESV) and the Reuters Events Automotive Summit.

The EV Report recently connected with Naganshi to take a deeper dive into SABIC and to learn more about how the company is supporting the electric vehicle industry.

Can you tell us about what SABIC is and the work that it does?

I am proud to be part of SABIC. We are one of the world’s largest diversified chemical companies with an expansive portfolio of material solutions spanning petrochemicals and polymers, specialty plastics, agri-nutrients , and metals.

SABIC focuses on sustainable and inclusive growth to help solve global challenges such as climate change. You can trace our sustainability commitment back to our founding in 1976, with a vision at that time to make use of waste gases that were being flared as a by-product of oil production. Today, sustainability is embedded in everything we do. This includes our most recent initiative dedicated to developing meaningful plastic materials and solutions to help the world shift to electric power and a lower carbon footprint.

What about SABIC’s work with EVs?

This work can be pivotal because the materials manufacturers choose today can help determine EV efficiency for years to come. We began preparing for the industry’s shift to EVs several years ago, which started with building an understanding of manufacturers’ challenges and unmet needs in this space. We knew that to realize the full potential of EVs, manufacturers would need to go beyond use of legacy metal materials, design and engineering practices. We assembled a global team of scientists and specialists to develop expertise, plastic materials and solutions. Today, all of this falls under our larger focused initiative at SABIC known as BLUEHERO™, designed to help our customers and their value chain partners advance the development of electrically powered products.

Can you tell us more about the EV products SABIC has developed?

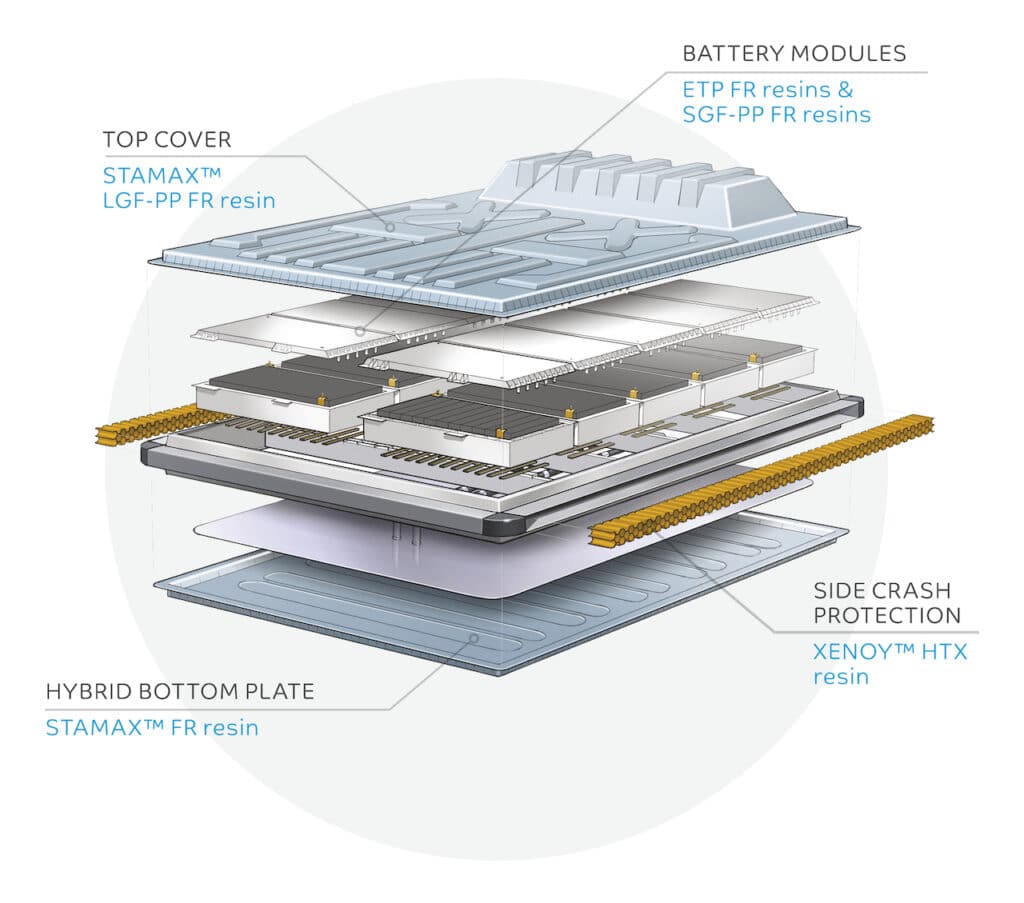

SABIC offers lightweight, high-performing plastic materials and solutions that can address a number of industry pain points. One of the best examples is a flame retardant polypropylene under our STAMAX™ resin brand. This long glass fiber material, when exposed to flames, can form a protective intumescent char on the surface of a battery part, such as the top cover of a battery pack. During this process, the material also foams, which further enhances the thermal resistance of the thermoplastic surface. This characteristic behavior of the material makes it an attractive solution to help potentially mitigate thermal runaway propagation within the battery module and from one battery module to others within the larger battery pack. As such, we are seeing tremendous interest in the material from industry because addressing thermal runaway is a critical focus for them.

Helping on that front is only the tip of the EV iceberg, if you will, because these same materials can help enhance EV battery systems in number ways: dropping weight to help support improved efficiency and range, expanded design freedom, reduced complexity for easier assembly and manufacturing, accelerated development time, lower costs, enhanced thermal management, lower environmental impact. Plastics have a number of benefits and advantages, and we are excited about bringing these to the EV value chain.

What are some of the products you’ve been involved in, and/or most excited about?

It’s not the products necessarily that I think we’re excited about, but our overall approach. We didn’t start by looking at individual part-by-part solutions. We have followed a holistic systems-engineering approach to identify how best to overcome some of the challenges that manufacturers are facing to meet requirements and make advancements. In some cases, this has meant embracing multi-material solutions rather than trying to force a fit between our plastics and application needs.

Under this approach, we have been looking at the battery pack as a whole and have developed concepts that capitalize on the use and value of lightweight thermoplastics. On a component basis, within these concepts, manufacturers can potentially realize 30-50% in weight savings and other key advantages.

To give some specifics on what a more plastic-intensive battery pack would look like in terms of mass-production, we’re looking at:

- Integration of individual batteries into pouch cells placed within custom molded, thin-walled housing.

- Geometric features such as double wall construction, novel rib patterns, and creative functional integration that helps reduce weight while still meeting structural requirements.

- Creative thermal management performance, as well as an optimized thermal transfer for the battery tray that meets drop-test requirements and absorbs the significant impact energy that side frame members can experience.

- Flame-retardant battery pack enclosures also allow the cover to be metalized to shield from electromagnetic interference and radio frequency interference.

- Parts reduction and assembly efficiency, resulting in cost savings enabled through the design freedom and flexibility offered by thermoplastics.

All of these potential advances as a whole is exciting. Overall, I think we’re inspired to have this opportunity to share our materials, expertise and solutions with industry and potentially contribute to pushing the boundaries of what is possible so manufacturers can deliver the full capabilities of EVs.

What do these innovations mean for the EV industry, and the direction in which the industry is going?

The materials, expertise and solutions that we are bringing to the table, we believe, are catalysts for re-thinking the design, engineering and production of EVs. In that way, we strive to do our part to help encourage robust innovation in this space.

It is important to remember that no one player can make the shift to electrification all on their own. Collaboration and partnerships are driving the EV industry forward. We have understood this from day one and that’s why collaboration is one of the pillars of our BLUEHERO electrification initiative. We’re supporting the readiness of industry to advance EV technologies, faster, but that can only be done if the value chain works together – not in silos.

Can you tell us more about SABIC’s collaboration with Formula E?

If you have not been to a Formula E race, you should go. The competitive on-track action is exciting. I think for SABIC – we identified with Formula E’s mission to accelerate sustainable progress. They are doing it through a motorsport, recognizing that sport itself can be a force for good in the world and potentially help drive technology advancements and speed up EV adoption so we can counteract climate change. We believe in what Formula E is doing, and that is why we entered into a major long-term sponsorship and partnership with them in July 2022. For us, this new relationship underscores our support and commitment to help the world move to an electric future.

As part of this new partnership, we are exploring opportunities to work with Formula E on potential EV technology innovations – which may ultimately help drive further safety, efficiency and performance enhancements.

What was behind SABIC’s move into developing products for the EV industry?

Multiple motives, if you will. At a basic level, the automotive industry and customers in other sectors are moving towards electric power and they need solutions and support to get there. We knew that we could play a role in facilitating this seismic shift and we had a responsibility to step up and do what we always strive to do – help our customers respond to emerging needs and trends. At another level, we’re increasingly cognisant of the need for resilient, more sustainable products that can help move the world to a low-carbon future. Our BLUEHERO electrification initiative is designed to help us develop those products, working with our customers and the value chains in which they operate.

Click here to learn more about SABIC