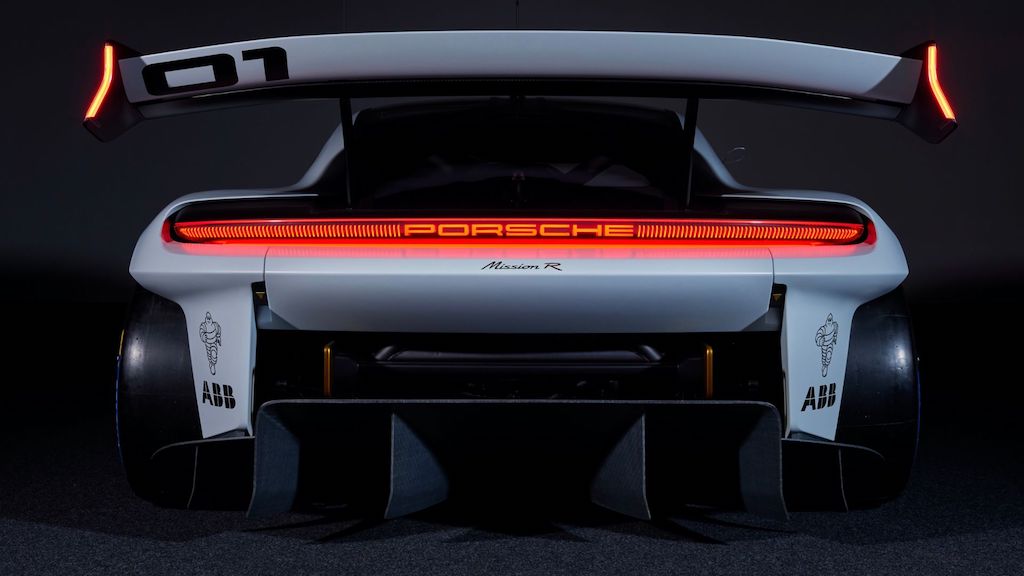

The Mission R is the latest vision from Porsche. With this study of an all-electric GT racing car, the pioneer of sustainable mobility is revealing what customer motorsports could look like in the future. A look at the drive.

“It’s indescribable; the immediate surge of power from the two electric motors is something you simply have to experience for yourself,” says Timo Bernhard, discussing the drive system of the Mission R. The Porsche brand ambassador and former works driver knows the technical basis behind the concept study and has already been on the race track with the technology platform as a test driver. “The only time I’ve ever experienced such an amazingly powerful boost was in the Le Mans-winning Porsche 919 Hybrid car.”

The Mission R is on a par with the performance level of the Porsche 911 GT3 Cup. The power output remains constant over the duration of the race, so there is no thermally induced de-rating – a major advantage of the electric motors with direct oil cooling developed by Porsche. The electric motor on the front axle produces up to 320 kW (435 PS) in race mode.

In qualifying mode, the all-wheel-drive car has a peak system output of more than 800 kW (1,088 PS). The continuous system power in race mode is 500 kW (680 PS). Top speed is more than 300 km/h. The lightweight electric racing car, which tips the scales at around 1,500 kg, accelerates from zero to 100 km/h in less than 2.5 seconds.

You might also like: AUDI EXPANDS HYBRID LINEUP WITH A3 SPORTBACK 45 TFSI E

The capacity of the battery, which also incorporates high-end cells and direct oil cooling, is designed for sprint racing. Thanks to 900-volt technology and fast-charging capability, it is possible to charge the battery from five to 80 percent SoC (State of Charge) in about 15 minutes during a break from racing. Another highlight is the very high recuperation output of up to 800 kW.

The power output from the two electric motors is transmitted to the front and rear wheels via straight-toothed input gearboxes and mechanical limited-slip differentials. The modular design of the drive system also helps to improve cost efficiency in customer motorsports: the gearbox, electric motors, and pulse-controlled inverters (PCI) on the front and rear axles are identical.

The Mission R is pre-equipped for over-the-air technology. It is conceivable, therefore, that, in the event of problems occurring during the race, Porsche Motorsport experts from Weissach would be able to access data from the customer cars via a remote interface and then help with troubleshooting.

Highly efficient e-motors with direct oil cooling

In the Mission R, Porsche is offering a preview of the next generation of electric motors. In 2018, a team of Porsche engineers and technicians in Zuffenhausen and Weissach began to develop extremely powerful and highly efficient electric motors.

The most important innovation of these permanently excited synchronous machines (PESMs) is the direct oil cooling of the stator, which enables very high peak and continuous power output levels to be achieved, in addition to delivering a very high level of efficiency. While in conventional electrical machines the cooling fluid flows through a jacket outside the stator, in the case of direct cooling, the oil flows directly along the copper windings. This allows more heat to be dissipated directly at source. In addition, the slots in the stator can be made smaller, which leads to greater efficiency in real driving cycles. An innovative stator seal is used to prevent the coolant from entering the rotor chamber.

As with the Taycan’s electric motors, the hairpin winding contributes to a high yield of power and torque while maintaining compact dimensions. The coils consist of rectangular wires that are bent and then inserted into the stator’s laminated core. Their shape is reminiscent of hairpins, hence the name. The open ends are welded together by laser.

An optimization algorithm was used to determine the optimum shape and position of the magnets in the rotor. The resulting geometry eliminates an old conflict of objectives: it combines excellent electromagnetic properties with high mechanical strength at very high speeds. During production, the magnets are inserted into the rotor laminations and extrusion-coated with plastic. As a result, they do not move, despite high centrifugal forces, and the balancing quality of the rotor remains stable. At the same time, the plastic helps to dissipate the heat generated in the magnets.

High-end battery and 900-volt technology

The battery sits behind the driver in an e-core layout. Its total capacity is 82 kWh. This means it is designed for a sprint race format distance of 25 to 40 minutes. High-end cells are used to benefit from the high power density. Here again, direct oil cooling offers tremendous thermal advantages – because it makes use of the entire surface of the cells, a large amount of heat can be transported from the battery into the cooling system.

Based on the 800-volt technology of the three-time Le Mans winner, the 919 Hybrid, the Porsche Taycan was the first car to enter production using this system voltage instead of the 400 volts normally used in electric cars. In the Mission R, Porsche is raising the bar a notch higher again with a voltage rating of more than 900 volts. Using 900-volt technology will result in further improvements in continuous power, weight, and charging time. At DC fast-charging stations, the Mission R can be charged from five to 80 percent SoC (State of Charge) within approximately 15 minutes. The maximum charging capacity is 350 kW. The charge port is located beneath the middle of the spoiler.

Special high-voltage alert system for the pit crew

As a matter of principle, the high-voltage safety concept of the Mission R meets the same high standards of safety as those required for series production vehicles. This means that, in the event of a collision, the battery connections to the vehicle and the high-voltage consumers are automatically disconnected to ensure no voltage is present. There is also an alert system designed specifically for the pit crew: special LEDs behind the windscreen and on the roof provide fast and detailed information on the operating status of the high-voltage system. If the LEDs light up green, the Mission R is high-voltage safe. If the LEDs are red, on the other hand, only high-voltage trained personnel should approach the vehicle. There is also a light in the roof module behind the speed-measuring pitot tube, which is included in this color-coded warning system.