New Northampton facilities represent a £15m investment over the last five years to support the automotive industry’s rapid decarbonization

MAHLE Powertrain announced the completion of two new facilities in Northampton, the result of a £15m investment over the last five years (including £3.6m of UK Government funding). These purpose-built facilities will allow MAHLE Powertrain to support customers with every aspect of development for the future of mobility, permitting the safe testing of vehicles, batteries, and hydrogen technologies under even the most extreme simulated environmental conditions. Amid unprecedented demand, the company is delighted to declare the center open for business by Andrew Lewer, MP for Northampton South.

“We’re extremely proud of our new test facilities which complement our end-to-end development process,” said Simon Reader, MAHLE Powertrain’s Managing Director. “As the industry accelerates the development of a new generation of vehicles that will offer carbon-neutral solutions for the transport sector, it creates a huge demand for testing facilities. Our new center has been designed with both battery and future-fuelled vehicles in mind and provides a spread of capabilities that is almost unique anywhere in the world.”

Andrew Lewer, MP for Northampton South, said: “I’m delighted to be able to declare this important new facility open for business. MAHLE Powertrain’s investment recognizes the huge wealth of engineering talent in this country, and this region in particular – a stone’s throw from the heart of British motorsport – with 160 skilled technicians and engineers already employed at the site.”

Through extensive investment in recent years, MAHLE Powertrain has been able to significantly bolster its engineering capabilities. This has been vital in supporting the automotive industry as it looks to develop future mobility solutions.

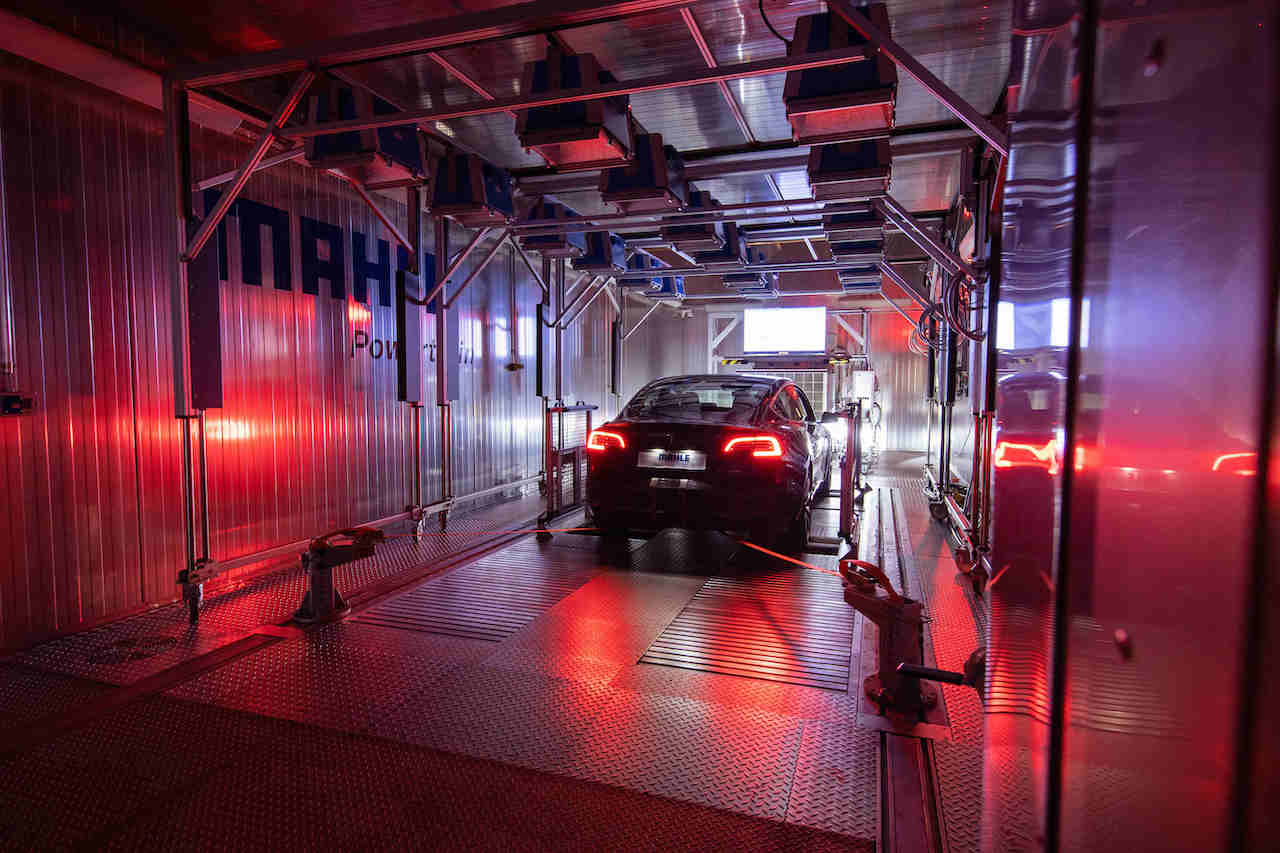

The new Vehicle Development Centre (VDC) is a state-of-the-art facility that allows manufacturers to test two- and four-wheel-drive vehicles in a variety of conditions and circumstances. The VDC can replicate the conditions found in the coldest arctic climates and the hottest arid deserts, as well as the humidity of a tropical rainforest or the pressure experienced at high altitudes. In addition, the VDC is designed to support the testing of hydrogen-fuelled technologies, with safety features to monitor and vent any escaping gases.

Creating a new battery testing facility in collaboration with the National Grid allows the company to develop and test battery packs internally without wasting energy. This complements the service offering to customers and helps save energy and resources.

The new Vehicle Development Centre supports the testing and verification of next-generation electric and hydrogen-fuelled vehicles. The facility’s test chambers can accommodate both two- and four-wheel-drive vehicles tested at speeds up to 155mph. Climatic conditions can be simulated from -40°C to +60°C with humidity ranging from 10% to 80%, while pressure control allows altitudes up to 5,000m (16,400ft) to be simulated. Hydrogen-fuelled technologies can be rigorously tested in chambers that monitor and safely vent any escaping gases. The new battery testing facility, meanwhile, with its own substation and dedicated National Grid connection, has the capability to test battery packs of up to 1MW with full fire protection in the event of a thermal runaway.

MAHLE Powertrain’s new facility is already garnering interest from automotive manufacturers across the globe. These manufacturers are keen to capitalize on the facility’s capabilities and MAHLE’s expertise in developing innovative solutions.