Sign up for our popular daily email to catch all the latest EV news!

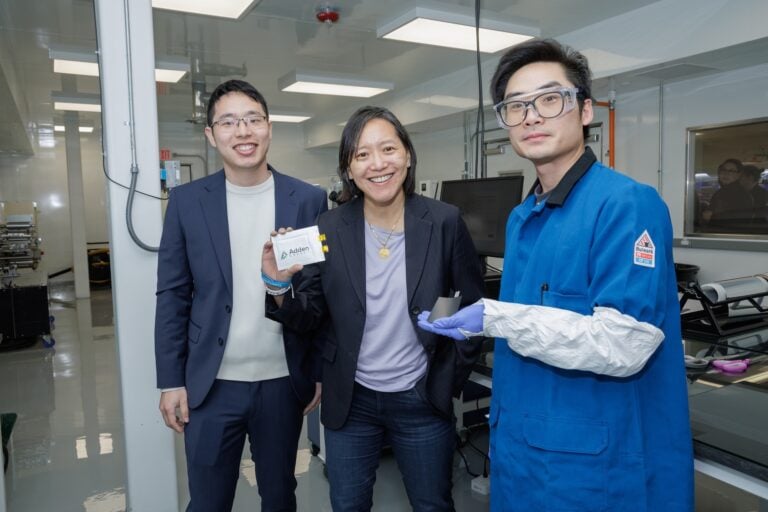

Altilium has released a new video showcasing its facility and the company’s ambitious goal to supply 50% of the UK’s critical battery metals through recycling by 2040. Located in Plymouth, the 18,000-square-foot ACT 2 facility uses advanced technology to recover over 95% of cathode metals from used electric vehicle (EV) batteries.

This initiative not only supports sustainable practices but also positions Altilium as a leader in producing high-quality battery materials for the automotive industry, matching or exceeding the performance of newly mined resources.

Key Highlights:

- Massive Recycling Goals: Altilium aims to provide 50% of lithium and nickel, and over 80% of graphite, for EV batteries by 2040, reducing reliance on mining.

- Innovative Technology: The ACT 2 facility in Plymouth recovers over 95% of cathode metals, a process unmatched in scale within the UK.

- Top-Quality Materials: Research from Imperial College London shows Altilium’s recycled materials rival virgin-mined metals, offering longer battery life and faster charging.

- Industry Collaboration: The UK Battery Industrialisation Centre (UKBIC) is now processing Altilium’s recycled materials, marking a significant step forward for UK battery production.

Dr. Christian Marston, Altilium’s COO and co-founder, emphasized this vision, stating, “The future minerals needed for electrification don’t have to come from mining.” This approach tackles both environmental concerns and the growing demand for battery materials. Meanwhile, CTO Dr. Ben Wickham highlighted the facility’s achievements, saying, “It’s really exciting that we’re doing processes in this company at scales that no one in the UK has ever done before.” These efforts showcase a breakthrough in recycling technology, producing materials that compete with commercial standards.

Beyond technical feats, Altilium’s work has broader implications. Richard LeCain, CTO at UKBIC, noted, “As the industry evolves, we want more performance all the time, and we need to deal with the cost of the materials and the supply of the material. Recycling is a big part of that to help alleviate those concerns.” By partnering with leading institutions like UKBIC and leveraging research from Imperial College London, Altilium is paving the way for a more sustainable and cost-effective EV battery supply chain. As of February 25, 2025, the company’s progress signals a promising future for the UK’s role in the global shift toward cleaner energy solutions.

Sign up for our popular daily email to catch all the latest EV news!