What’s Happening: Alumobility, a global association promoting the adoption of aluminum in automotive manufacturing, highlights the importance of lightweighting electric vehicles (EVs) with aluminum to achieve better performance, safety, and sustainability. Aluminum content in vehicles is expected to grow by 24% over the next decade, reaching nearly 260 kg (570 lbs) per vehicle by 2030.

Why It Matters: With a 62% increase in battery-electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) sales in the first half of this year compared to 2021, automakers are working to address concerns such as high upfront costs, limited driving range, and lengthy charging times to gain wider market acceptance. Increasing aluminum content in EVs can significantly contribute to solving these issues.

Key Points:

- Battery efficiency: Lightweighting with this material can lead to better efficiency, quicker charging, and longer range for BEVs, as well as allowing for more passengers and cargo without compromising range.

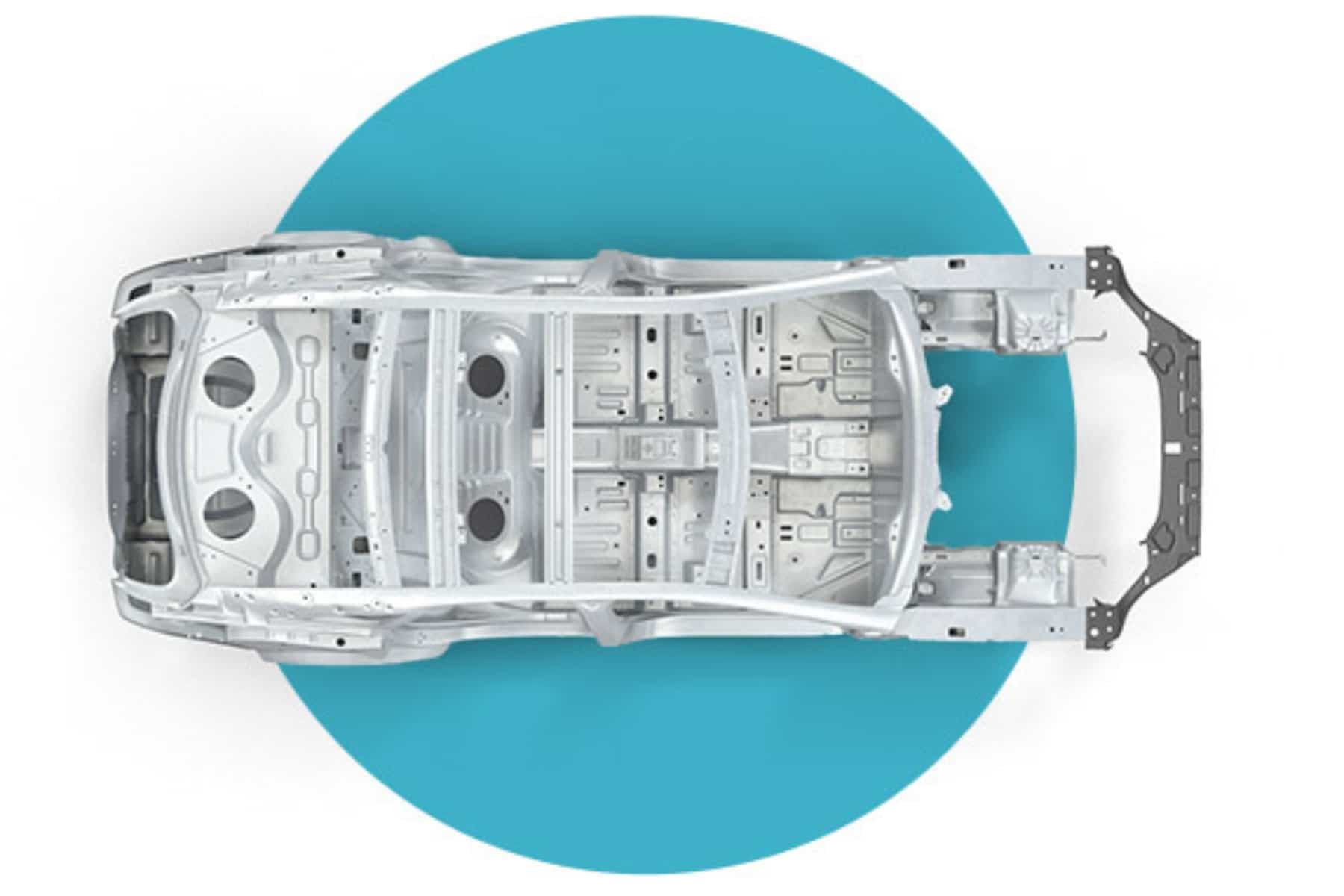

- Performance and safety: Aluminum provides better handling, acceleration, steering, braking, and durability, while also absorbing more energy in a crash compared to steel, thus enhancing overall vehicle safety.

- Environmental benefits: Lighter vehicles with smaller battery packs reduce the environmental impact associated with large battery manufacturing. Aluminum can be recycled in a closed-loop process, further reducing carbon emissions and waste.

Bottom Line: The adoption of aluminum in automotive manufacturing can lead to more efficient, better-performing, safer, and more sustainable vehicles. As a result, both EV startups and legacy automakers are increasingly choosing aluminum as their primary material for building the vehicles of the future.