Sign up for our popular daily email to catch all the latest EV news!

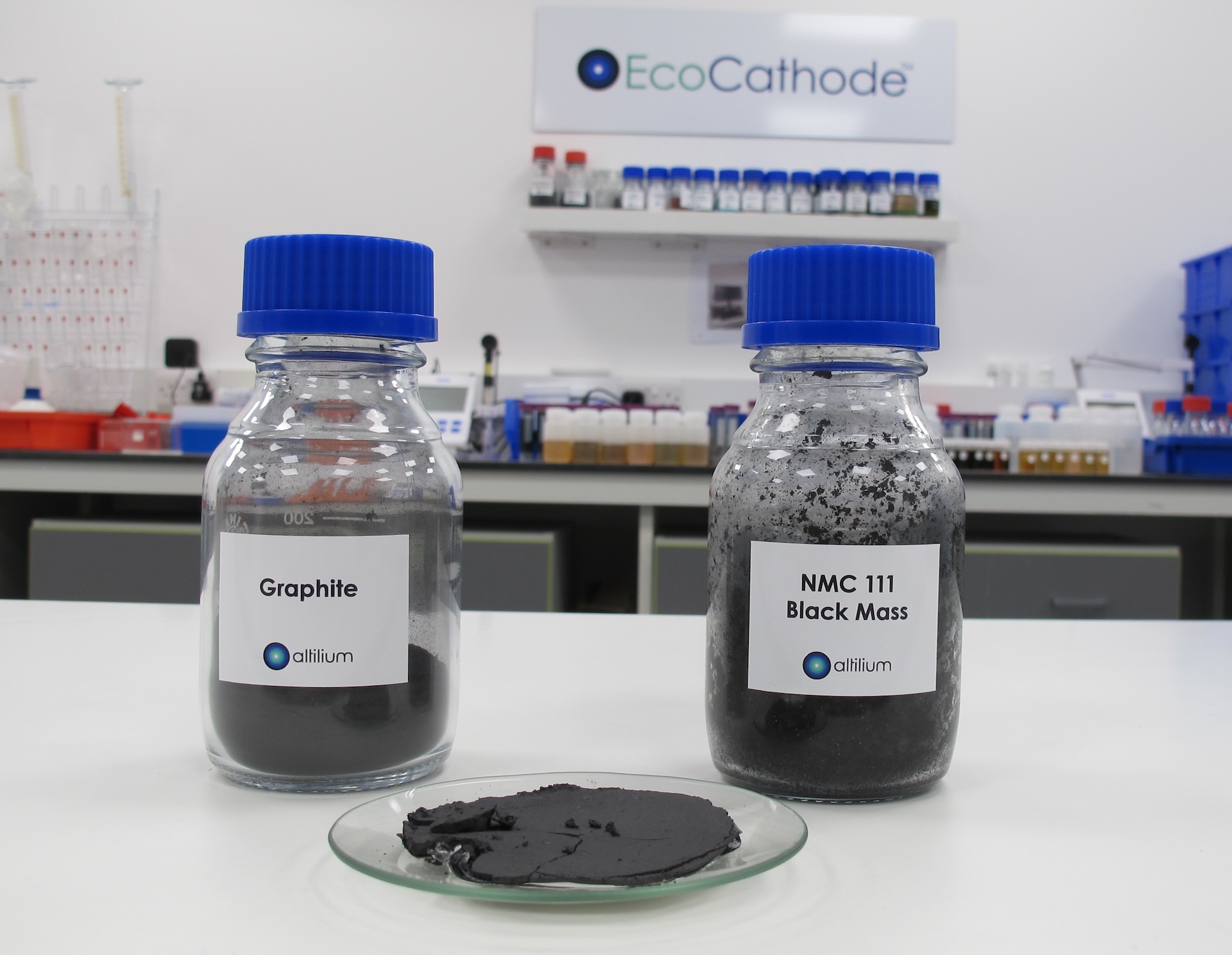

Altilium and Talga Group Ltd have embarked on a strategic partnership aimed at enhancing the sustainability of electric vehicle (EV) battery production through the recovery and reuse of graphite. This collaboration leverages Altilium’s advanced recycling technology and Talga’s expertise in green anode production, setting a precedent for sustainable practices within the UK’s EV battery industry. The initiative underscores both companies’ dedication to reducing carbon emissions and the reliance on imported raw materials by promoting a circular economy.

Key Highlights:

- Partnership Between Altilium and Talga for sustainable graphite recovery from waste EV batteries.

- Focus on Circular Economy: Emphasizes reusing recovered graphite in new battery anodes.

- Contribution to UK’s Self-sufficiency: Aims to reduce reliance on imported raw materials and support domestic graphite supply.

- Innovative Recycling and Production Processes: Over 99% of graphite recovery rate and low CO2 emissions in anode production.

- Strategic Response to Global Supply Challenges: Addresses potential graphite supply shortages and export controls.

- Significant Capacity for Graphite Recovery: Altilium’s Teesside plant to meet over 20% of UK demand by 2030.

- Support for EV Battery Recycling Targets: Both companies aim to reduce the CO2 footprint and enhance battery circularity.

This partnership between Altilium and Talga represents a significant step toward the realization of a sustainable and self-sufficient EV battery production ecosystem in the UK. By focusing on the recovery of graphite—a critical component in lithium-ion batteries—the collaboration not only aims to meet the growing demand for sustainable battery materials but also addresses the environmental challenges associated with battery production and waste.

Dr. Christian Marston, Altilium’s President and COO, highlighted the importance of this partnership in achieving a sustainable future for EV batteries, stating, “This breakthrough is a significant milestone in our journey towards a more sustainable and environmentally-friendly future for electric vehicle batteries.” Talga Group CEO, Mr. Martin Phillips, also emphasized the critical need for a localized anode supply to support the growing EV market, underscoring the partnership’s role in optimizing the use of recycled graphite.

As the EV market continues to expand, initiatives like the one between Altilium and Talga are essential for promoting sustainable practices, reducing environmental impact, and ensuring the long-term viability of the EV battery supply chain.

Sign up for our popular daily email to catch all the latest EV news!