Sign up for our popular daily email to catch all the latest EV news!

Factorial Inc. has unveiled its first Solstice™ all-solid-state battery cells with a 40Ah capacity, showcasing a significant milestone in scaling all-solid-state battery technology. These A-sample cells, manufactured using a novel dry cathode coating process, highlight the potential for sustainable, energy-efficient, and cost-effective battery production. This breakthrough positions Factorial as a leader in advancing battery technology for electric mobility applications.

Key Highlights

- 40Ah capacity cells are designed for automotive applications, achieving higher energy density.

- The dry cathode coating process eliminates hazardous solvents, reducing environmental impact and manufacturing costs.

- Solstice™ cells offer up to an 80% increase in energy density, enhancing their viability for electric mobility.

- The advanced design eliminates energy-intensive formation processes, cutting operating costs and improving sustainability.

Factorial’s 100% dry cathode coating process is a revolutionary step in battery manufacturing. Traditional cathode coating processes rely on hazardous, carcinogenic solvents that require energy-intensive recycling procedures. Factorial’s innovative dry coating approach removes this need, making the process safer, more efficient, and environmentally friendly. Moreover, the all-solid-state design eliminates the need for formation processes, further reducing energy consumption.

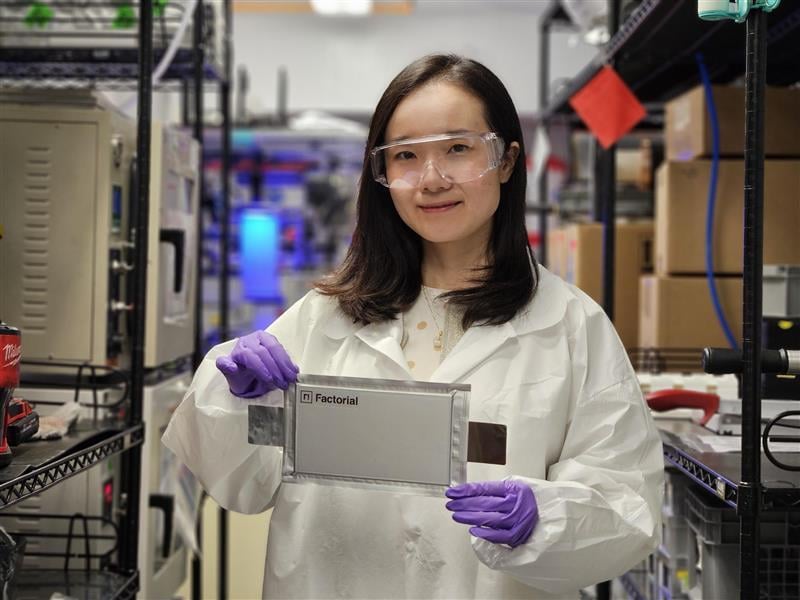

Dr. Siyu Huang, Factorial Co-Founder and CEO, emphasized the importance of scalability:

“Breakthrough solid-state battery performance is only relevant if it can be scaled to a size that is viable for commercial use. At 40Ah capacity, our all-solid-state, Solstice™ cells demonstrate the technical maturity, process validation, and scalability required for commercial applications.”

Developed at Factorial’s advanced center in Massachusetts, the 40Ah Solstice™ cells utilize custom equipment for the dry cathode coating process. Lifecycle testing has shown smaller prototypes achieving over 2,000 cycles, reinforcing their durability and reliability.

Alex Yu, Factorial CTO and Co-Founder, highlighted the transformative impact of the dry electrode coating process:

“Factorial is a leader in advancing this novel manufacturing process for larger-sized cells, which has been a significant challenge for the rest of the market. Coupled with long cycle life and high energy density, Factorial’s Solstice™ all-solid-state battery cell is poised to deliver advancements in safety, range, and cost that automakers are looking for.”

The Solstice™ platform complements Factorial’s FEST® (Factorial Electrolyte System Technology), developed in partnership with Mercedes-Benz. Beyond passenger vehicles, Solstice™ batteries are also suited for energy storage, consumer electronics, and commercial vehicles.

About Factorial Inc.

Factorial Inc., headquartered in the U.S., is a pioneer in solid-state battery technology. Their innovative platforms, FEST® and Solstice™, provide solutions offering extended range, enhanced safety, and cost competitiveness. Factorial collaborates with global automakers, including Mercedes-Benz, Stellantis, Hyundai, and Kia, to develop scalable, high-performance battery systems. For more information, visit Factorial Energy.

Sign up for our popular daily email to catch all the latest EV news!