Customer-oriented while saving resources at the same time: Porsche introduces its multi-stage service concept for high-voltage batteries.

Porsche is setting itself goals more ambitious than ever before: by 2025, half of all new Porsche sales are expected to be electrified – either fully electric or as plug-in hybrids. By 2030, we expect the share of all new Porsche vehicles with an all-electric powertrain to be more than 80 percent. The sports car manufacturer is taking a holistic approach when it comes to electrified vehicles with high-voltage batteries. The Porsche concept covers sourcing and manufacturing, consulting, sales and servicing, and logistics and recycling.

The transition from combustion engines to electric motors is changing today’s service business, especially in the Porsche dealership organization. Porsche Aftersales is systematically preparing its dealers for this change with its ‘Road-to-X Initiative’. Among other things, it includes measures designed to increase service loyalty and to boost productivity in workshops.

“Our dealers are the face we present to the customer and our brand ambassadors on the front line,” says Daniel Schukraft, Vice President Aftersales and Customer Care at Porsche. “We are working intensively on a plan of action for our dealership organization to ensure that it is as well prepared for the age of electromobility as possible.”

At the same time, the repair concept for high-voltage batteries makes a significant contribution to sustainability and resource conservation. At the start of its battery development process, Porsche looks beyond traditional considerations linked to whether or not the component is feasible to produce. The development teams also make sure that the construction of the energy carrier is as simple as possible, so that it can be repaired at qualified Porsche Centres later in its life cycle. For example, 28 or 33 modules are installed in the various Taycan derivatives, depending on the battery capacity. The battery housing can be opened to allow the replacement of cell modules and other components. Enabling such detailed repairs is also advantageous for customers from a price perspective.

“The total battery capacity is determined by the worst cell – if a cell loses capacity, it limits the range,” says Christian Brügger, Product Engineer in Porsche’s Aftersales Electrics division. “We can detect a defective cell using the diagnostic tester in the workshop. For example, if the voltages don’t match, we know which module needs to be replaced before the repair.”

In order to meet its customers’ interest in the capacity and condition of the high-voltage battery, Porsche made early efforts to enable analysis for the Taycan in workshops using Porsche diagnostic equipment. Details of the readout process were sent out to Porsche Centres at the beginning of March 2022, enabling them to read out the data independently and send it to customers. Porsche also plans to offer an app solution that will enable customers themselves to find out the health status of their vehicle.

Cell modules that are still functional but no longer suitable for powering a vehicle can be used for stationary tasks. As part of its second-life strategy, Porsche is working on a pilot project that will allow high-voltage batteries to be re-used. These batteries are dismantled down to the module level and installed in stationary energy carriers. Working with the Volkswagen Group and other professional partners, Porsche has been making ongoing improvements to its existing recycling processes with the aim of increasing the proportion of raw materials in circulation and in order to re-use these materials in new batteries.

Multi-stage service concept for electric vehicles

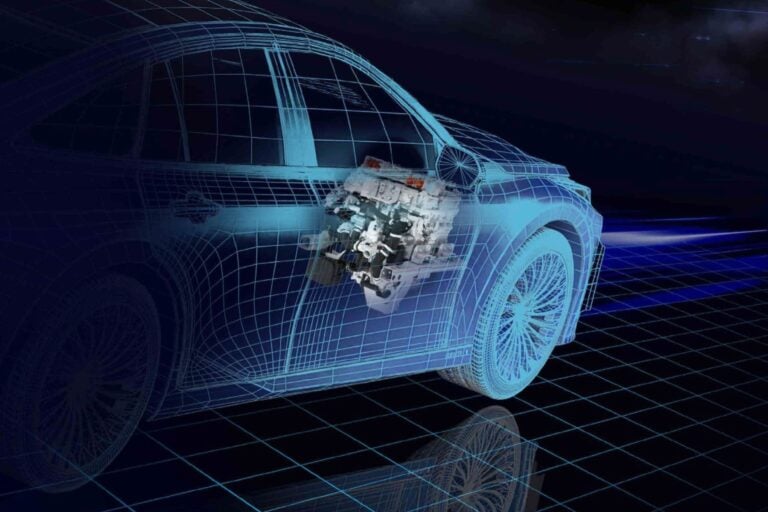

A holistic concept for servicing all-electric Porsche vehicles has also been developed. As the sports car manufacturer’s first all-electric model, the Taycan has some very different service and repair needs compared to vehicles with combustion engines. For example, the electric sports car has a service interval of two years or 30,000 kilometers. However, since tasks such as spark plug and oil changes are no longer relevant, the scope of maintenance is likely to be reduced by around 30 percent, as initial indicators in relation to the Taycan reveal. In addition, the electric powertrain, including the high-voltage battery, is completely maintenance-free. However, repair work on electric vehicles requires expert training and specialist tools that Porsche Centres must obtain before they can offer these services.

The service concept for electric vehicles, therefore, comprises several stages: the basis for this is the high-voltage support center, which is specifically configured for HV battery repairs, has suitable specialist tools, and has specially trained high-voltage experts as well. The sports car manufacturer is also establishing cross-regional hubs at certain qualified centers, which will handle repairs on high-voltage vehicles in areas where there is no high-voltage base close by. The Porsche Centre that originally accepts the vehicle for repairs will take it to the high-voltage hub, where the work will be carried out along with a final quality inspection before it is returned to the original Porsche Centre.

If transporting the vehicle to a dedicated repair center is not possible, a ‘flying doctor’ repair technician will be deployed. These mobile high-voltage experts can repair defective high-voltage batteries on-site. Ahead of this, the relevant Porsche Centre receives all the high-voltage tools and replacement parts required for the work. This creates a comprehensive service network for high-voltage battery repair.

Three qualification levels for repair work

Last but not least, work on the Taycan, as the first production vehicle with a system voltage of 800 volts, also requires a clear division of tasks and responsibilities. With this in mind, Porsche has defined three qualification levels: qualified electricians, high-voltage technicians, and high-voltage experts. Qualified electricians have a basic qualification that allows them to perform standard repairs to high-voltage vehicles, such as changing the tires or wiper blades. They must be briefed and supervised by a high-voltage technician when working on a high-voltage vehicle.

High-voltage technicians are trained to work on vehicles that have been disconnected from the voltage supply, and are familiar with classifying and storing lithium batteries. They are also qualified to remove and pack high-voltage batteries classified as ‘Normal’ and ‘Warning’. High-voltage experts have the highest qualification level at a Porsche Centre. They are the only people allowed to perform work inside high-voltage batteries, handle high-voltage batteries with insulation faults and prepare and pack these types of batteries for transportation.

The know-how necessary to work with high-voltage systems is taught in a specially coordinated training concept for all task areas. “We offer the qualification as a high-voltage technician as part of a train-the-trainer approach,” says Stefan Schierle, HV Trainer at Porsche Aftersales. “Local market trainers in the respective country qualify the high-voltage technicians at Porsche Centres. We currently only train high-voltage experts centrally at the on-site training center at Porsche. From 2022 onwards, however, we intend to organize this in a decentralized manner and plan to establish eight training locations worldwide.”