Recycled graphite composite improves battery performance and more

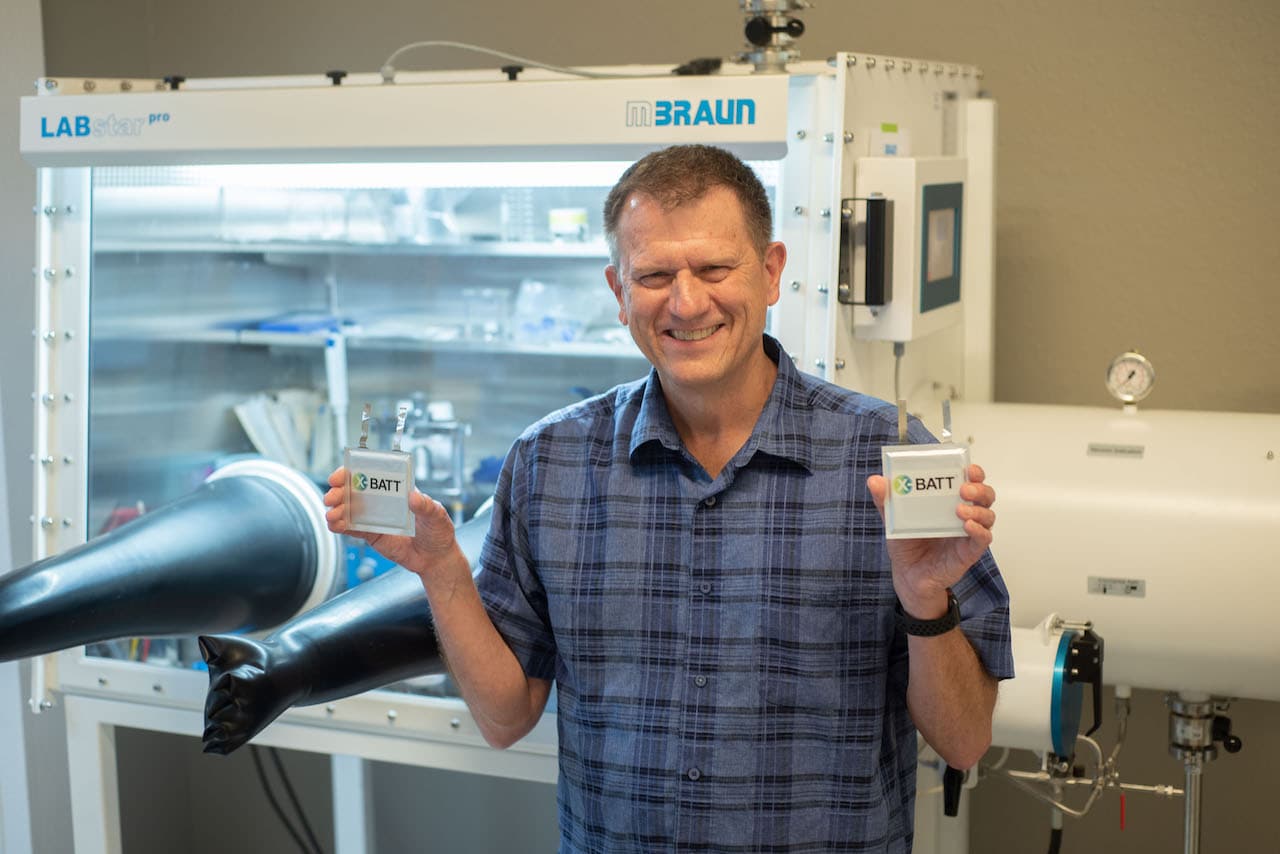

ORLANDO, Fla. – X-BATT is getting closer than ever to producing more powerful batteries by reusing waste graphite that usually ends up in landfills.

X-BATT is using the company’s patented, high-performance polymer technology along with recycled graphite from spent lithium-ion batteries to engineer a composite anode that outperforms traditional materials. The recycled graphite is highly contaminated and cannot currently be reused in batteries – until now.

“Graphite isn’t an unlimited resource and the U.S. imports all its battery-grade graphite from foreign countries. X-BATT’s team is combating this challenge by discovering innovative ways to reuse waste graphite and create new batteries that are just as powerful, if not more so, as their traditional counterparts – something many people thought would never be possible,” said Bill Easter, founder of X-BATT®.

The innovative company is ready to begin sharing some of its discoveries with the world. March 28 to 31, X-BATT will be presenting their revolutionary battery results at the 39th annual International Battery Seminar & Exhibit at Loews Royal Pacific Resort in Orlando.

The benefits of this new material don’t stop at its increased performance, this technology could also lead to a domestic source for anode material, helping the United States reduce reliance on foreign countries for the critical materials necessary to support the increased demand for electrification.

Demand for lithium-ion batteries continues to grow, with no signs of it slowing down. Each year, demand is expected to grow by 25 percent resulting in 14x growth by 2030. X-BATT® revolutionary discovery can help meet this demand in an eco-friendlier way.

To help further its research, the Department of Energy’s National Energy Technology Laboratory (NETL) awarded Semplastics, X-BATT’s parent company a $1 Million contract to produce polymer-derived ceramic composite anodes using coal as a carbon source for lithium-ion batteries. The company has discovered that adding a carbon source, such as coal, to the PDC material offers stability and normalizes charge/discharge behavior, improving cycling life and decreasing nominal voltage.

“The energy race is in full swing and we’re proud to be running full speed toward an eco-friendly, long-term solution to power our world,” said Easter.