Electric motor production in Charleston benefits local customers and supports global growth of Bosch electromobility business

Charleston, S.C. – Electrification means new opportunities. As more electric vehicles come to market and provide consumers with the option for zero-tailpipe emission vehicles, new opportunities in manufacturing and jobs are emerging to support the shift to electrification. Bosch announced today the launch of production of electric motors at its Charleston, S.C. manufacturing facility. Additionally, the company plans to invest more than $260 million to further expand production of electrification products at the site, which is expected to create at least 350 net new jobs by 2025.

“We have grown our electrification business globally and here in the North American region,” said Mike Mansuetti, president of Bosch in North America. “We’ve invested more than $6 billion dollars in electromobility development and in 2021 our global orders for electromobility surpassed $10 billion dollars for the first time. Local production helps to advance our customers’ regional electrification strategies, and further supports the market demand for electrification.”

Expansion complemented by investment

Production of electric motors at the Charleston site began in October. It covers approximately 200,000 square feet in an existing building on the Bosch Charleston campus. The new assembly area includes the production of rotors and stators, and the final assembly of the electric motor.

The company has secured additional electromobility business that requires further expansion at the plant. An additional approximately 75,000 square feet will be added onto the existing building to make room for future production. The total investment for the expansion will be more than $260 million for the expansion and new high-tech manufacturing equipment. The expansion is expected to be operational by the end of 2023.

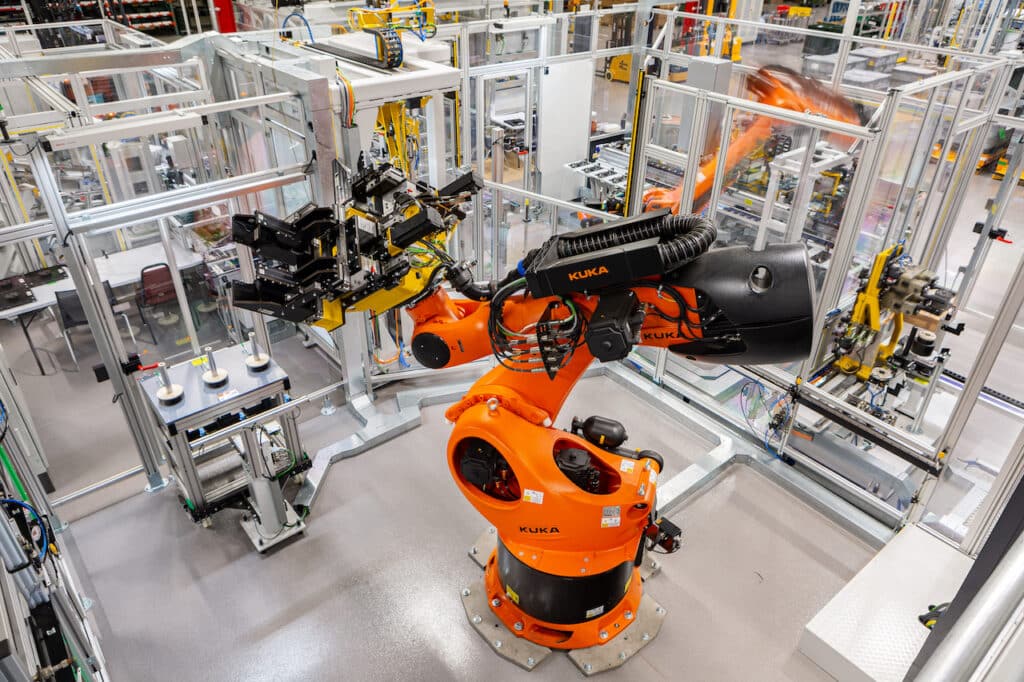

The Charleston plant stands out with a long history of process competency as well as its knowledge in the area of automation and robotics. Production at the site features highly-automated processes, and the site utilizes artificial intelligence and Industry 4.0 methods to gain more efficiency.

“As more electrified solutions come to the market, the strong footprint and skilled workforce in South Carolina is well established to help organizations bring these solutions to the market,” said South Carolina Governor Henry McMaster. “We are grateful for another strong commitment from Bosch to our state.”

Bosch has continued to invest in its presence in South Carolina. To move ahead the vision of sustainable mobility, Bosch announced its fuel cell stack production lately in August in Anderson, South Carolina, as part of a more than $200 million investment also expected to create at least 350 new jobs by the start of production in 2026.

“Bosch is paving the way by showing the growth opportunities for existing manufacturing facilities that support new technology,” said South Carolina Secretary of Commerce Harry M. Lightsey III. “Congratulations to Bosch on another major investment in South Carolina.”

The Bosch Charleston facility, which opened in 1974, is the largest manufacturing site in the United States for Bosch from an employment perspective with around 1,500 associates. It covers more than 900,000 square feet of floor space located on 118 acres.

“We are proud of our long-term relationship with the Bosch team and congratulate them on their latest expansion in Dorchester County,” said Dorchester County Council Chairman Bill Hearn. “Bosch’s decision to bring electric vehicle technology to Dorchester County is yet another example of our ongoing commitment to help our businesses and industries prosper.”

Charleston reinvents to support electrification

The newly launched production of electric motors is located in a building formerly occupied by production of diesel components. Bosch announced in January 2020 that production of diesel powertrain components would be slowly ramped down. The site indicated it would secure electrification business.

“This launch delivers on a commitment to our associates and to the local community in Charleston,” said Mansuetti, who started his Bosch career as a manufacturing engineer at the Charleston facility. “We are in the midst of major shifts in mobility, and the story of reinvention in Charleston is a model for how electrification production can evolve from within an existing facility. We are building on the long-standing expertise and commitment of the Charleston team with this new production.”

As part of the site transformation, Bosch has provided reskilling and upskilling opportunities to associates to prepare for the production of electric motors. This includes associates traveling to other sites within the global Bosch production network for training and best practice sharing.

Bosch is also collaborating with local schools to begin implementing fundamentals related to electrification into curriculum. The Bosch Community Fund, the corporate foundation for Bosch in North America, has invested more than $2.5 million in grants related to STEM education efforts in the Charleston area since 2013.

The energy that drives electric vehicles

An electric motor converts electrical energy into mechanical energy to provide propulsion in electric vehicles. At the Charleston facility Bosch will produce the rotor and stator and the final assembly of electric motors that will drive electric vehicles on the road in the United States. A rotor is the rotating part of the motor and contains a precise design of magnets to create a magnetic field. A stator is static and made up of electric coils that are fed energy from alternating current coming from the power electronics via the battery. As current flows into the stator, the magnetic field of the rotor will chase the magnetic field in the stator, creating the motion that is transferred to the wheels of the vehicle.

The Bosch approach to electric motor development is flexible and allows easy integration in different vehicle topologies based on customer needs while still providing competitive costs. The company uses approaches such as bar winding technology to maximize power density while minimizing size, which enables more freedom in the electric motor layout. Thinner lamination tailored to customer needs provides greater efficiency. As electric motors continue to develop, Bosch is enlisting the help of artificial intelligence and new design methods to continue to optimize development, efficiency, performance and use of materials.

Electric motors from Bosch can deliver anywhere from 50 kilowatts to up to 500 kilowatts with torque ranging from 150 Nm to 1000 Nm. They feature up to 98 percent efficiency, which helps to maximize range of the vehicle. With a voltage range up to 850V, Bosch has developed electric motors suited for a variety of applications from passenger cars to light commercial vehicle use.

As its orders in electromobility continue to increase, the Bosch global production network has been ramping up to support the expanding demand for electrification. Local-for-local production supports a robust supply chain approach for local customer needs.

“We have long been believers in the potential of electromobility and we have been investing heavily to bring this technology to market at scale for our customers,” Mansuetti said.

The Bosch site in Charleston supports multiple products from the Bosch Mobility Solutions portfolio. It produces high-pressure fuel injectors and pumps for internal combustion engines. It also manufactures safety-related products such as electronic stability control or ESP®, an anti-skid technology that is estimated to have saved more than 9,000 lives in the U.S. from 2008-2015 according to the National Highway Traffic Safety Administration (NHTSA).