Sign up for our popular daily email to catch all the latest EV news!

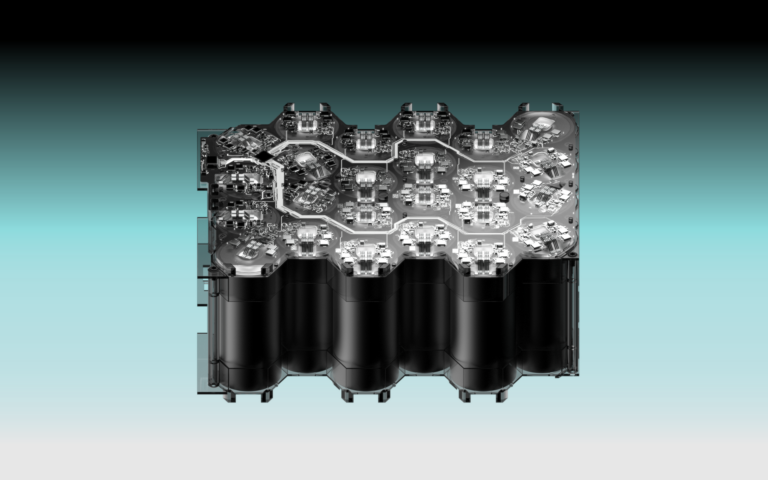

Battery technology company Coreshell has secured $24 million in strategic funding to scale production of its innovative lithium-ion battery anodes made with 100% domestically sourced metallurgical silicon. The funding, led by Ferroglobe and Zeon Ventures, will enable Coreshell to expand its manufacturing capabilities and deliver commercial samples of its 60 Ah battery cells to global automakers in 2025.

Key Highlights:

- Innovative Anode Technology: Coreshell’s batteries utilize domestically sourced metallurgical silicon, replacing traditional graphite, to achieve higher energy density and lower costs.

- Production and Delivery Plans: The funding will scale production at Coreshell’s California facility and support the delivery of commercial samples to automakers in 2025.

- Strategic Investors and Partners: The round was led by Ferroglobe, a key supplier of silicon materials, and Zeon Ventures, highlighting strong industry backing.

The funding will specifically support the scaling of production at Coreshell’s newly-built 4 MWh manufacturing facility in San Leandro, California, with plans underway for a separate 100 MWh facility to meet future demand. Additional investors in the round include Lane Ventures, Entrada Ventures, Foothill Ventures, Helios Climate Ventures, Translink Investment, Trousdale Ventures, and Asymmetry Ventures, reflecting broad support for Coreshell’s vision.

Coreshell’s CEO, Jonathan Tan, emphasized the significance of this milestone. “This strategic funding round is a critical step in scaling production and delivering commercial samples to leading automakers who have already tested the low-cost metallurgical silicon anodes in our cells with promising results and are eager to receive commercial-scale cells for further validation,” said Tan. “As the global EV industry reaches an inflection point, automakers recognize that alongside range, supply chain resilience – driven by reliance on foreign countries for graphite production – and cost reduction are key to overcoming adoption barriers. Coreshell is addressing these challenges by replacing graphite with domestically sourced metallurgical silicon, reducing costs, strengthening the supply chain, and improving sustainability.”

The company’s battery technology has shown remarkable performance in testing, with cells providing 30-40% higher energy density than graphite-based alternatives, over 475 cycles with greater than 90% capacity retention, and the ability to charge from 10-80% in under 15 minutes. These achievements will be showcased at the 2025 International Battery Seminar, underscoring Coreshell’s potential to transform the EV battery landscape.

With this funding and its strategic partnerships, Coreshell is poised to play a pivotal role in advancing the electric vehicle industry by providing more efficient, cost-effective, and domestically sourced battery solutions.

Sign up for our popular daily email to catch all the latest EV news!