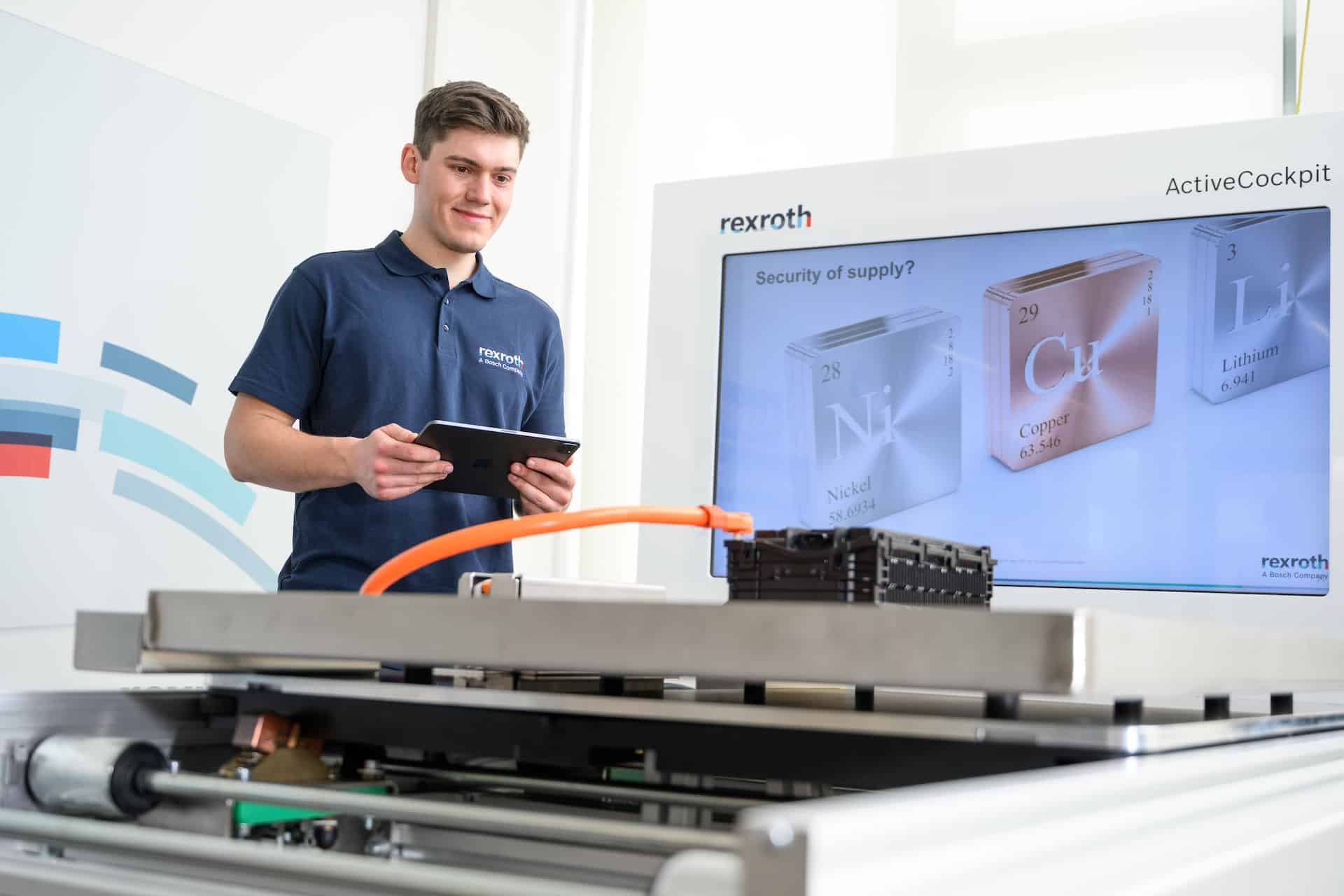

What’s Happening: Bosch has developed an automated system for discharging and disassembling electric vehicle (EV) battery modules, increasing efficiency and safety in the recycling process. The technology will be provided to Battery Lifecycle Company, a joint venture between REMONDIS subsidiary TSR Recycling and Rhenus Automotive, for use in Europe’s first fully automated battery recycling plant in Magdeburg.

Why It Matters: With the rapid growth of EV adoption and the increasing demand for batteries, efficient recycling of raw materials such as lithium, cobalt, and nickel is crucial for a sustainable circular economy. By 2030, Europe is predicted to require recycling capacity for up to 420,000 metric tons of battery material per year.

Key Points:

- Bosch’s automated discharging system can deep-discharge a battery module in just a few minutes, reducing risks of short circuits and fires.

- The Magdeburg plant will recycle up to 15,000 metric tons of battery materials per year and is expected to be operational in summer 2023.

- Bosch’s recycling technology builds on its existing experience in automation and manufacturing technology for battery production.

Bottom Line: Bosch’s automated battery recycling technology could revolutionize the recycling process for EV batteries, helping to establish a sustainable and efficient circular economy. This development is essential in meeting the increasing demand for raw materials in battery production as EV adoption continues to grow.