Stellantis has announced a significant investment of over $406 million in three Michigan facilities to advance its multi-energy strategy. This investment will support the company’s push towards electrification, focusing on retooling plants for electric vehicle (EV) production and enhancing manufacturing flexibility. This aligns with the company’s broader “Dare Forward 2030” strategic plan aimed at carbon neutrality and adapting to evolving market demands.

Key Highlights:

- Sterling Heights Assembly Plant (SHAP): $235.5 million investment for the production of Ram 1500 battery-electric and range-extended models.

- Warren Truck Assembly Plant (WTAP): $97.6 million to support future electrified Jeep Wagoneer production.

- Dundee Engine Plant (DEP): Over $73 million for battery tray production and beam machining to complement gas engine assembly.

- Dare Forward 2030 Plan: Targeting 100% BEV passenger car sales in Europe and 50% in the U.S. by 2030, with carbon neutrality by 2038.

Stellantis’ Strategic Investment Overview

Stellantis’ $406 million investment across Michigan will support the development of electric vehicles while maintaining production flexibility for internal combustion engines (ICE). This move is part of its multi-energy strategy, designed to balance electrification with existing technologies.

Sterling Heights Assembly Plant (SHAP)

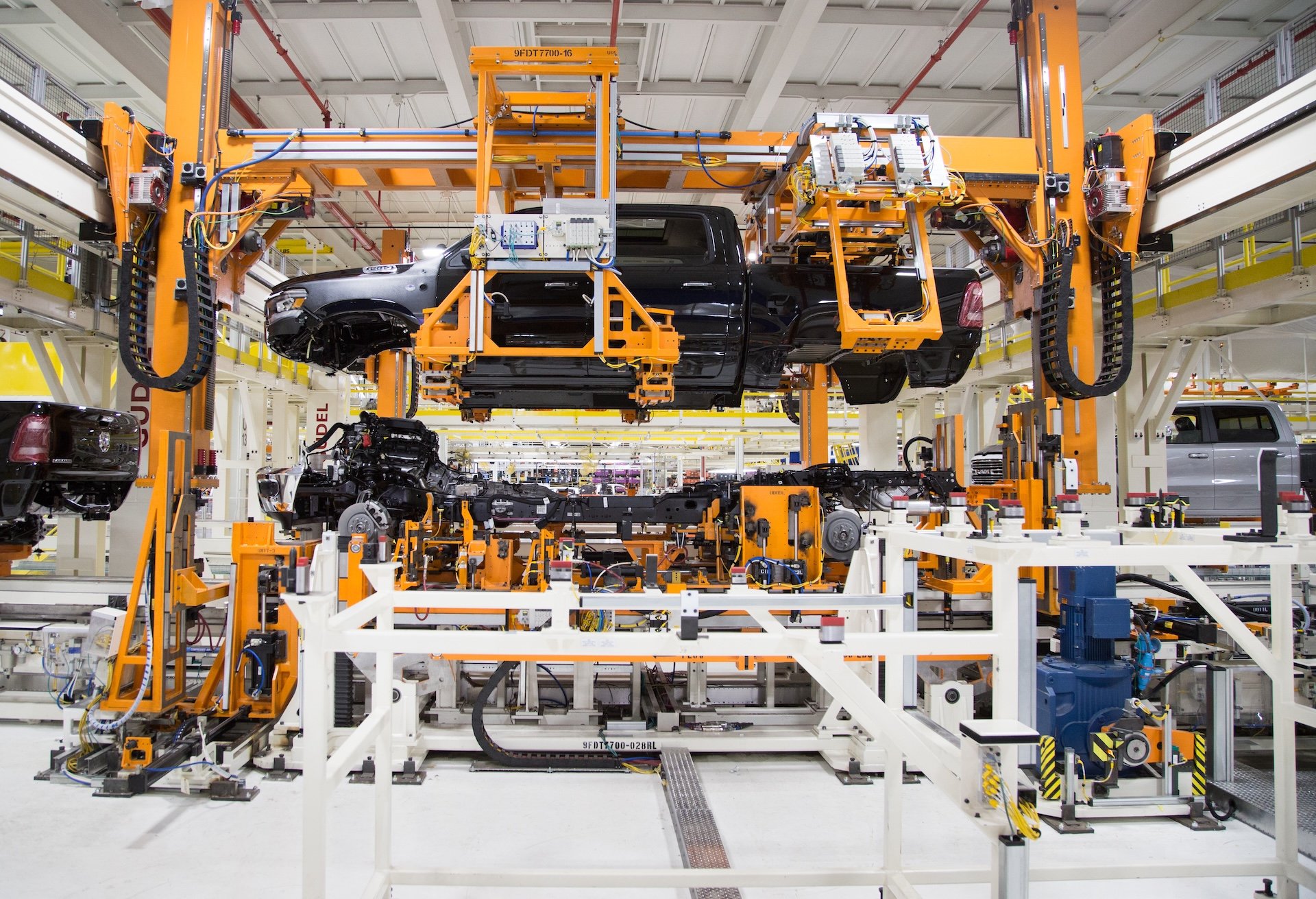

A significant $235.5 million investment will retool the Sterling Heights plant to produce the Ram 1500 REV, Stellantis’ first fully electric pickup truck, alongside the range-extended 2025 Ram 1500 Ramcharger. The plant’s retooling was completed ahead of schedule, enabling it to manufacture ICE, BEV, and hybrid models on the same line.

Key features of the Ram 1500 REV include:

- Up to 500 miles of range with the optional 229 kWh battery pack.

- The Ram 1500 Ramcharger offers 663 horsepower and 14,000 lbs. of towing capacity.

Warren Truck Assembly Plant (WTAP)

An investment of $97.6 million at WTAP will support the production of future electrified Jeep Wagoneer models. These EVs will be manufactured alongside existing ICE versions, ensuring the plant can handle both technologies on one production line.

Dundee Engine Plant (DEP)

The Dundee Engine Plant will receive more than $73 million for battery tray assembly and beam machining to support Stellantis’ STLA Frame and STLA Large architectures. These components will be integrated into future EV production while maintaining flexibility for gas engine assembly.

Stellantis’ Dare Forward 2030 Plan

Stellantis’ broader Dare Forward 2030 initiative includes a commitment to invest over €50 billion in electrification over the decade. The company aims to achieve a 100% BEV sales mix in Europe and a 50% sales mix in the U.S. by 2030, supported by 400 GWh of battery capacity from plants in North America and Europe. Stellantis also targets carbon neutrality by 2038.

This multi-energy approach positions Stellantis to meet customer demand for both ICE and electric vehicles, ensuring long-term competitiveness in a rapidly evolving market.

For more information, visit Stellantis.

Sign up for our popular daily email to catch all the latest EV news!